Nov . 15, 2024 07:22 Back to list

travel rain jacket factories

Exploring Travel Rain Jacket Factories A Guide to Quality and Innovation

In the world of outdoor gear, a reliable rain jacket is an essential item for any traveler. With the unpredictability of weather, especially for those who frequently trek through rugged landscapes or explore urban environments, a high-quality travel rain jacket can mean the difference between a comfortable adventure and a damp, miserable experience. In this article, we will delve into the intricacies of travel rain jacket factories, focusing on their production processes, innovations, and the importance of sustainability.

Production Processes

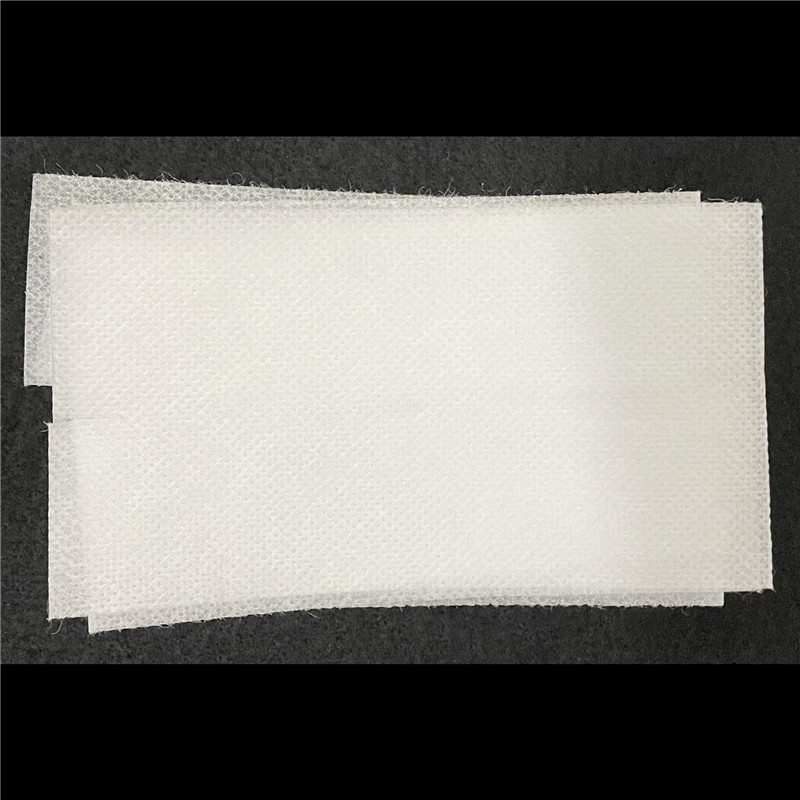

Travel rain jacket factories employ a combination of traditional craftsmanship and modern technologies to produce their garments. The manufacturing process typically begins with the selection of materials. Most rain jackets are made from waterproof or water-resistant fabrics, such as nylon or polyester, often coated with a layer of polyurethane (PU) or polyvinyl chloride (PVC) for enhanced moisture protection.

Once the materials are sourced, they undergo a cutting and stitching process. Advanced factories utilize computerized cutting machines to ensure precision and minimize waste. Skilled workers then carefully stitch the fabric pieces together, reinforcing seams to prevent water from seeping through. Factories invest in state-of-the-art machinery that can replicate intricate designs while maintaining the integrity of the waterproofing features.

Quality control is a crucial step in the manufacturing process. Each jacket is rigorously tested for its water resistance, breathability, and overall durability. This ensures that the final product meets the high standards expected by consumers, particularly those who rely on their gear in challenging weather conditions.

Innovations in Design

travel rain jacket factories

The travel rain jacket market has witnessed significant innovations in recent years. Manufacturers are continually researching and developing new technologies to enhance the performance of their products. For instance, the introduction of breathable fabrics allows moisture from perspiration to escape while preventing rain from entering, keeping the wearer dry on both the outside and inside.

Additionally, many factories are incorporating smart features into their designs. Jackets with built-in ventilation systems, adjustable hoods, and pockets designed for easy access to travel essentials have become popular. Some brands even incorporate lightweight insulation for colder climates without sacrificing packability, making these jackets ideal for travelers who prioritize convenience and versatility.

Sustainability Efforts

As environmental concerns become increasingly pressing, many travel rain jacket factories are adopting sustainable practices. This includes using recycled materials, such as recycled polyester, and minimizing water usage during the production process. Factories are also exploring eco-friendly waterproofing options that avoid harmful chemicals.

Moreover, brands are focused on creating durable products that can withstand the test of time, reducing the need for frequent replacements. By fostering a culture of responsible manufacturing, these companies not only appeal to eco-conscious consumers but also contribute positively to the planet.

Conclusion

Travel rain jacket factories play a pivotal role in producing the essential gear that enables adventurers to explore the great outdoors, regardless of the weather. With a keen focus on quality, innovation, and sustainability, these factories are shaping the future of outdoor apparel. As consumers become more discerning about their purchases, understanding the production processes behind travel rain jackets will help them make informed choices that align with their values and enhance their travel experiences. With the right rain jacket, any journey—rain or shine—can be an enjoyable adventure.

-

100% Waterproof PVC/PEVA Kids Poncho | Hoodie Rain Wear

NewsAug.21,2025

-

PVC/PEVA Sleeves: Durable Protection for Workshop & Labour Safety

NewsAug.19,2025

-

Waterproof Kid Apron with Sleeves: PEVA/PVC for Painting Fun!

NewsAug.18,2025

-

36x90" Double Zipper Post Mortem Bag - Secure & Reliable

NewsAug.17,2025

-

Waterproof PVC/Vinyl Work Apron - Heavy-Duty Protection

NewsAug.16,2025

-

Heavy Duty Post Mortem Bag - 36x90, Double Zipper

NewsAug.15,2025