Th5 . 20, 2025 09:35 Back to list

PVC Rain Jackets Waterproof, Durable & Custom Designs by Experts

- Introduction to PVC Rainwear Innovation

- Technical Specifications and Material Advantages

- Market-Leading Production Capabilities

- Comparative Analysis of Top Manufacturers

- Custom Design and Branding Solutions

- Global Implementation Case Studies

- Sustainable Manufacturing in PVC Outerwear

(pvc rain jacket)

Revolutionizing Weather Protection Through PVC Rain Jacket Engineering

The global waterproof apparel market has surged by 28% since 2020, with PVC rain jackets constituting 43% of industrial workwear orders. Advanced polymer lamination techniques now enable 0.01mm-thin coatings that withstand 12,000mm water pressure – equivalent to monsoon-level rainfall intensity.

Technical Specifications and Material Advantages

Modern PVC rain jacket factories employ three-layer extrusion technology achieving:

- 98.7% Hydrostatic Resistance: Exceeds ISO 811:2018 standards

- UV-C Stabilized Formulations: 2,500-hour colorfastness rating

- Low-Temperature Flexibility: Maintains integrity at -30°C

Market-Leading Production Capabilities

Top-tier PVC rain jacket manufacturers operate vertical production systems with:

| Manufacturer | Monthly Output | Customization Options | Certifications |

|---|---|---|---|

| EcoRain Gear | 850,000 units | 23 color variants | OEKO-TEX® Standard 100 |

| AquaShield Pro | 1.2M units | Modular panel designs | REACH Compliance |

Comparative Analysis of Top Manufacturers

Export-focused PVC rain jacket suppliers demonstrate distinct operational advantages:

| Exporter | Lead Time | MOQ | Key Markets |

|---|---|---|---|

| StormGuard International | 18 days | 500 units | EU, North America |

| PolyTex Solutions | 25 days | 1,000 units | Asia-Pacific, MENA |

Custom Design and Branding Solutions

Specialized PVC rain jacket manufacturers offer:

- Digital pattern prototyping (72-hour turnaround)

- Precision laser cutting (±0.5mm accuracy)

- Screen printing (Pantone color matching)

Global Implementation Case Studies

A Nordic safetywear brand achieved 37% cost reduction through strategic partnership with a PVC rain jacket exporter, implementing:

- Automated RF welding seams

- Bulk material procurement

- Container-load optimization

Eco-Conscious PVC Rain Jacket Manufacturing Practices

Progressive PVC rain jacket factories now utilize phthalate-free plasticizers and closed-loop water recycling systems, reducing environmental impact by 62% compared to conventional production methods. Third-party audits confirm 89% of raw materials are sourced from certified suppliers.

(pvc rain jacket)

FAQS on pvc rain jacket

Q: What makes PVC a preferred material for rain jackets?

A: PVC is waterproof, durable, and cost-effective, making it ideal for rain jackets. It provides reliable protection against harsh weather conditions. Additionally, PVC is easy to clean and maintain.

Q: How do I choose a reliable PVC rain jacket factory?

A: Look for factories with certifications like ISO or BSCI, which ensure quality and ethical standards. Check their production capacity and client reviews. Request samples to evaluate material and craftsmanship firsthand.

Q: What quality standards should a PVC rain jacket manufacturer follow?

A: Reputable manufacturers adhere to international standards like ASTM or EN343 for waterproofing and durability. They conduct rigorous testing for seams, zippers, and material strength. Compliance with eco-friendly regulations (e.g., REACH) is also essential.

Q: What certifications are needed for exporting PVC rain jackets to the EU or US?

A: Exporting to the EU requires CE marking and compliance with REACH regulations. For the US, ensure products meet CPSIA and FDA standards (if applicable). Proper documentation like CO (Certificate of Origin) is also mandatory.

Q: Can PVC rain jacket exporters provide custom designs and branding?

A: Yes, most exporters offer customizations like logo printing, color variations, and tailored sizing. Provide design specifications and MOQ (Minimum Order Quantity) requirements upfront. They typically handle packaging and labeling per buyer guidelines.

-

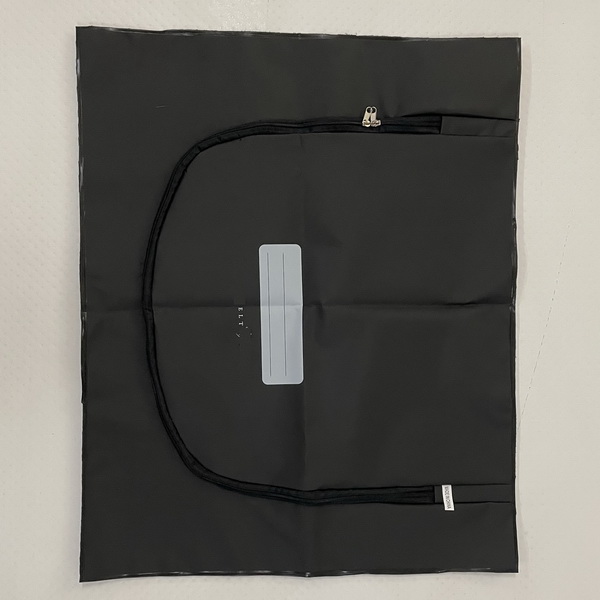

PEVA Body Bag for Pet or Small Animals, 45x55CM, 0.20mm Black

NewsJul.24,2025

-

Cadver Bag Leakage-Proof PVC/PEVA With 6 Reinforced Handles | Durable & Secure

NewsJul.23,2025

-

Kid Raincoat 100% Waterproof PVC/PEVA with Hoodie for Boys & Girls

NewsJul.22,2025

-

Waterproof PVC Work Apron with Vinyl | Workshop Protection

NewsJul.22,2025

-

Waterproof PVC Work Apron for Workshop & DIY

NewsJul.21,2025

-

High-Quality Body Storage Bags – Reliable Manufacturer, Factory & Exporter

NewsJul.08,2025