Desemba . 13, 2024 01:07 Back to list

Shroud-Based Transport Solutions for Efficient Factory Operations and Logistics

The Significance of Shroud Transport in Factory Settings

In today’s fast-paced industrial environment, the efficiency of production lines is paramount to the success of any factory. One crucial aspect of this efficiency lies in the shroud transport systems employed within these facilities. Shrouds play a vital role in protecting delicate components during their transit from one station to another, ensuring that products maintain their integrity whilst being manufactured. This article explores the significance of shroud transport in factory settings, detailing its benefits, challenges, and future perspectives.

The Significance of Shroud Transport in Factory Settings

The introduction of shroud transport systems has led to a remarkable improvement in manufacturing efficiency. By reducing the likelihood of product damage during transit, these systems contribute to lower waste rates and decreased downtime. A reduced need for rework or replacement translates to significant cost savings for factories. Furthermore, shroud systems often improve the speed at which products can move through the production line, allowing for a more streamlined operation. As factories seek to optimize their workflows, the integration of shroud systems can be an essential component of the overall strategy.

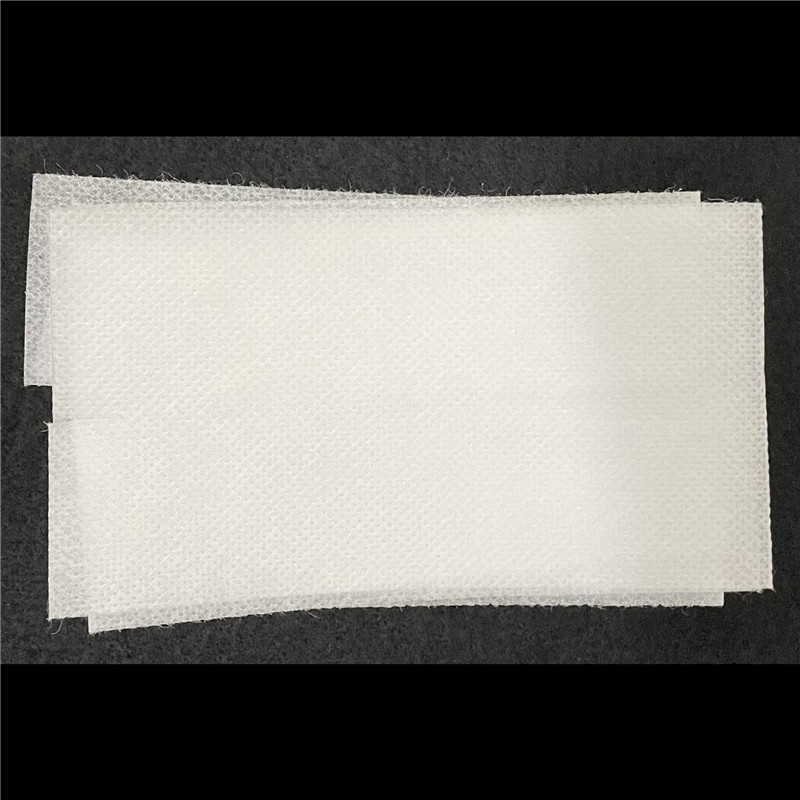

shroud transport factory

However, the implementation and maintenance of shroud transport systems are not without their challenges. One of the primary concerns is the initial investment required for the installation of these systems. While the long-term benefits are evident, the upfront costs associated with acquiring, installing, and maintaining shrouded transport mechanisms can be a barrier for some manufacturers. Additionally, ensuring that the shrouding materials are durable and suitable for the specific needs of the products being transported can be a complex task. Different industries may require custom solutions, adding to the design and production time.

Another challenge related to shroud transport is the need for regular maintenance and monitoring. Equipment failure, if not properly managed, can lead to significant delays in the manufacturing process. Therefore, factories must invest in trained personnel capable of conducting regular inspections and maintenance on shroud systems to ensure that they function correctly. Moreover, factories need to implement rigorous processes to handle any issues that arise, which can divert resources and attention from primary production activities.

Looking to the future, advancements in technology offer promising solutions to enhance shroud transport systems in factories. Automation, for instance, can revolutionize the way shrouded transport systems operate. Smart sensors could be integrated to monitor not only the integrity of the products within the shrouds but also the condition of the shroud systems themselves. Real-time data analytics could provide insights into potential issues before they escalate, leading to proactive maintenance and minimizing disruption to production schedules.

In conclusion, shroud transport systems play an indispensable role in modern factory settings, ensuring efficiency, reducing waste, and safeguarding sensitive products. While challenges remain in terms of initial costs and maintenance, the long-term benefits are compelling. As technology continues to evolve, future advancements promise to optimize these systems further, making them even more integral to the success of manufacturing operations. Companies that invest in these systems will likely find themselves better positioned to compete in an increasingly dynamic global market, highlighting the necessity of embracing innovation in manufacturing practices.

-

100% Waterproof PVC/PEVA Kids Poncho | Hoodie Rain Wear

NewsAug.21,2025

-

PVC/PEVA Sleeves: Durable Protection for Workshop & Labour Safety

NewsAug.19,2025

-

Waterproof Kid Apron with Sleeves: PEVA/PVC for Painting Fun!

NewsAug.18,2025

-

36x90" Double Zipper Post Mortem Bag - Secure & Reliable

NewsAug.17,2025

-

Waterproof PVC/Vinyl Work Apron - Heavy-Duty Protection

NewsAug.16,2025

-

Heavy Duty Post Mortem Bag - 36x90, Double Zipper

NewsAug.15,2025