Oktoba . 19, 2024 06:01 Back to list

Affordable Disposable Rain Gear Manufacturers for All Weather Conditions

The Rise of Disposable Rain Suits A Look into Factories and Manufacturing

In recent years, the demand for disposable rain suits has risen dramatically, driven by a combination of fashion trends, environmental factors, and practical convenience. These lightweight, protective garments are designed to be used once and discarded, addressing the needs of individuals facing sudden weather changes. But what goes into the production of these rain suits? Let’s explore the factories that manufacture them and the implications of this burgeoning industry.

Understanding Disposable Rain Suits

Disposable rain suits are typically made from polyethene or similar materials that are waterproof yet lightweight. They are primarily designed for events such as outdoor festivals, concerts, and sports events, where attendees may be exposed to unexpected rain. The appeal lies in their convenience; they can easily be packed away and pulled out when needed, saving individuals from getting drenched and uncomfortable.

Manufacturing Process

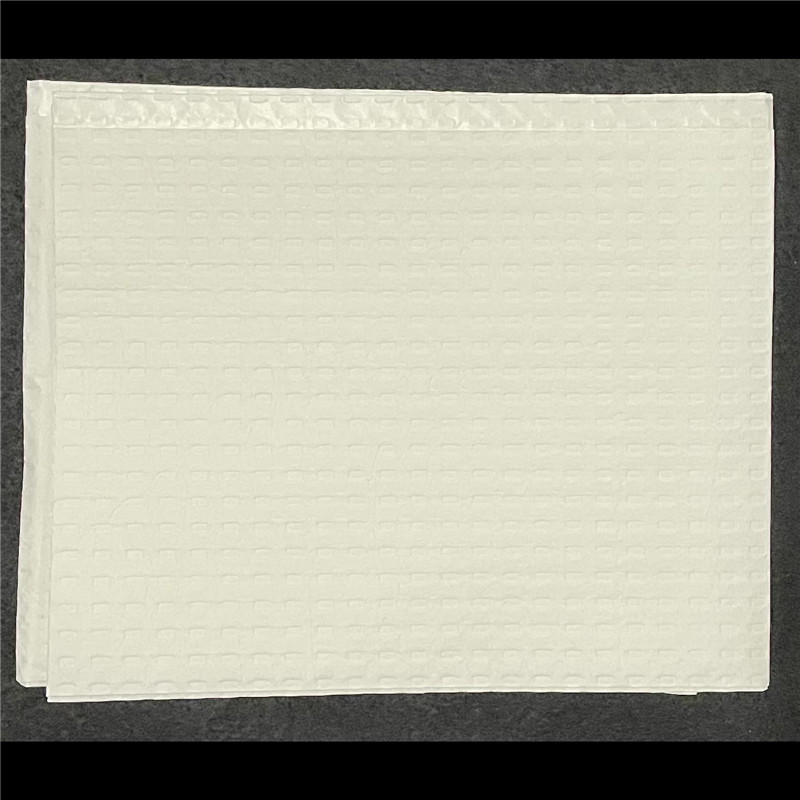

Factories that produce disposable rain suits often operate on a large scale, utilizing advanced machinery to cut, seal, and package the garments efficiently. The production process starts with raw material sourcing, with manufacturers opting for high-quality polyethylene films that provide durability without compromising on weight.

1. Cutting and Shaping The first stage involves rolling out sheets of polyethylene, which are then cut into the desired sizes and shapes using precision machines. This process ensures that the rain suits come in various sizes to accommodate different users.

2. Sealing After cutting, the pieces are joined together using heat sealing technology. This ensures that the seams are watertight, an essential feature for any rain suit. The sealing process is crucial because it determines the overall quality and effectiveness of the final product.

disposable rain suit factories

3. Quality Control Factories implement strict quality control measures to ensure that every batch of rain suits meets industry standards. This includes checking for leaks, ensuring proper sizing, and verifying the performance of the material against water penetration.

4. Packaging Once manufactured, the suits are folded and packaged in bulk for distribution. Given the nature of disposable products, factories often collaborate with retailers to ensure effective supply chain management, enabling quick delivery to consumers.

Environmental Considerations

Despite their convenience, disposable rain suits raise significant environmental concerns. Being single-use products, they contribute to the growing issue of plastic waste. Many factories are now exploring alternative materials, such as biodegradable plastics or recycled materials, to lessen the environmental impact. The introduction of these sustainable options is often accompanied by campaigns that encourage recycling and responsible disposal among consumers.

Future Trends

The market for disposable rain suits is evolving. As environmental awareness grows, consumers are increasingly seeking eco-friendly alternatives. Factories are responding by investing in new technologies and materials that promote sustainability. Furthermore, with the rise of online shopping, e-commerce has played a crucial role in the accessibility and distribution of disposable rain suits, making them readily available to a broader audience.

Conclusion

The factories that produce disposable rain suits are at the intersection of convenience and sustainability. While the demand for these products continues to grow, it is essential for manufacturers to balance production with environmental stewardship. As consumers become more ecologically conscious, the future of disposable rain suits will likely involve innovation and adaptiveness, paving the way for a more sustainable approach in the industry. Ultimately, the evolution of this product reflects broader societal trends towards convenience while also addressing the growing need for environmental responsibility.

-

PVC/PEVA Rainwear & Rainsuits: Durable, 0.20mm All-Weather Gear

NewsAug.08,2025

-

Kids PVC/PEVA Rain Poncho - 100% Waterproof with Hoodie

NewsAug.07,2025

-

Durable PEVA Pet Body Bag | 45x55CM | Custom Printing

NewsAug.06,2025

-

White PEVA PVC Pet Body Bag with Handle | Durable Portable

NewsAug.05,2025

-

White PEVA PVC Pet Body Bag w/Handle - Eco-Safe & Durable

NewsAug.04,2025

-

PVC/PEVA Waterproof Rainwear - Lightweight Protection

NewsAug.02,2025