Nov . 22, 2024 00:08 Back to list

waterproof body bag factories

The Evolution of Waterproof Body Bag Factories

In recent years, the demand for waterproof body bags has surged, particularly in industries such as law enforcement, military, and emergency services. This growing need has led to the proliferation of waterproof body bag factories around the globe. These factories not only cater to niche markets but also play an essential role in critical situations where protecting individuals from environmental factors is paramount.

Waterproof body bags are designed to safeguard human remains from moisture, contaminants, and various environmental hazards. The urgent requirement for such products has propelled advancements in manufacturing technologies and materials, enhancing quality and efficiency in production. The evolution of waterproof body bag factories has mirrored these advancements, incorporating innovative techniques and sustainable practices to meet the needs of modern consumers.

One of the key factors contributing to the rise of waterproof body bags is the increasing awareness of the importance of preserving human dignity in the most challenging circumstances. In cases of natural disasters, accidents, or crimes, the proper handling of bodies is crucial. Factories dedicated to the production of waterproof body bags have emerged as leaders in addressing this issue, providing reliable and respectful solutions during sensitive times.

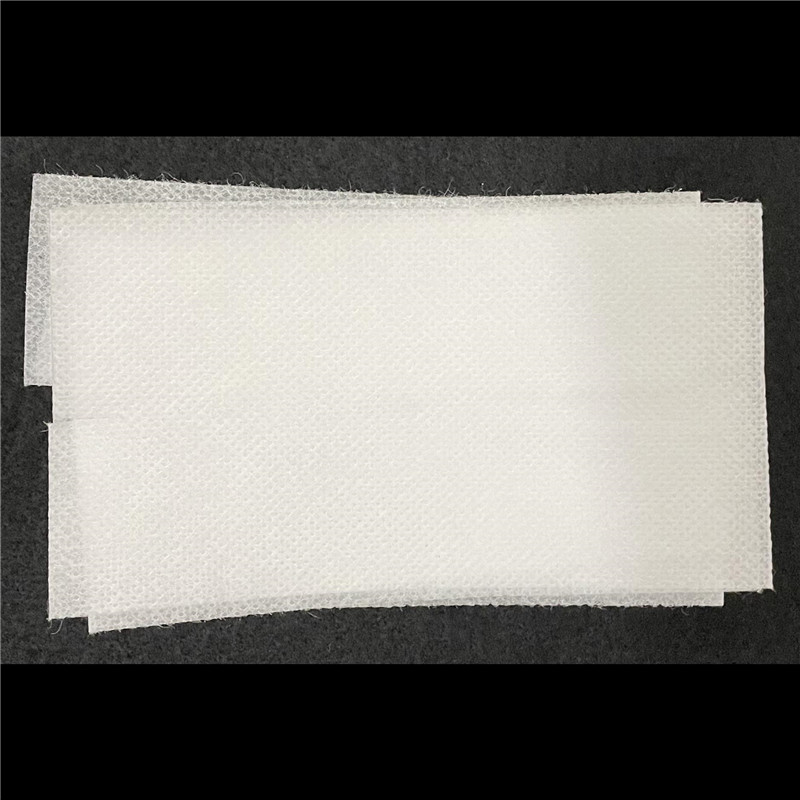

The materials used in waterproof body bags are primarily synthetic, ranging from heavy-duty polyethylene to advanced nylon blends, all engineered to provide maximum protection against moisture. These materials undergo rigorous testing to ensure their durability and efficacy, and manufacturers are continuously experimenting with new fabrics and technologies. For instance, some factories have started using biodegradable materials, aiming for an eco-friendly approach to body bag production, thus aligning with global sustainable development goals.

Furthermore, automation has significantly transformed the manufacturing process within these factories. Automated cutting machines, sewing robots, and quality control systems enhance productivity while maintaining high standards. As a result, waterproof body bag factories can scale their output to meet rising demand without compromising on quality.

waterproof body bag factories

Another critical aspect of waterproof body bag factories is their commitment to compliance with international standards. Many of these factories are certified under ISO standards, ensuring that their products meet stringent safety and quality requirements. This not only enhances their credibility but also builds trust with their clients, who rely on the products to perform in the most demanding conditions.

The globalization of supply chains has also impacted the manufacturing of waterproof body bags. Factories around the world now source materials from various countries, balancing cost-effectiveness with quality. This interconnectedness allows for the sharing of best practices and innovations across borders, ultimately benefiting consumers with better products.

In addition to traditional markets, the versatility of waterproof body bags has led to their adoption in unexpected sectors, including tourism and wildlife conservation. Factories are beginning to create custom solutions for expeditionary groups, aiding in the safe transport of equipment and, in some cases, the respectful management of deceased wildlife during research operations.

As we look to the future, waterproof body bag factories will continue to evolve, incorporating cutting-edge technology and sustainable practices into their production processes. The ongoing commitment to quality, innovation, and ethical considerations will ensure that these factories remain indispensable to a variety of industries, providing crucial solutions in times of need.

In conclusion, the landscape of waterproof body bag factories is continually changing, driven by the need for quality products that address real-world challenges. As societal values shift towards more respectful and environmentally friendly practices, these factories are at the forefront, ensuring that the products they offer not only serve their purpose but also honor the dignity of individuals during their most vulnerable moments.

-

High-Quality Body Storage Bags – Reliable Manufacturer, Factory & Exporter

NewsJul.08,2025

-

High-Quality PE Cadaver Bag for Pets Reliable Manufacturer & Supplier

NewsJul.08,2025

-

Medical Depot - Leading Medical Depot Factory, Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Work Raincoat – Reliable Manufacturer & Exporter Direct from Factory

NewsJul.07,2025

-

High-Quality Pet Dead Body Bag - Reliable Manufacturer, Factory & Exporter

NewsJul.07,2025

-

High-Quality Vinly Vest Manufacturer & Exporter Custom Vinly Vest Factory

NewsJul.06,2025