Jul . 11, 2024 08:15 Back to list

Manufacturers of plastic rain gear producing high-quality items for various markets.

Plastic Rainwear Factories A Look into the Manufacturing Process

Plastic rainwear factories play a crucial role in providing protection against the elements for people all around the world. From raincoats to ponchos, these factories produce a wide range of waterproof apparel that keeps individuals dry during rainy weather. But have you ever wondered how these essential items are manufactured? In this article, we will take a closer look at the process involved in producing plastic rainwear.

The first step in manufacturing plastic rainwear is the selection of materials. Typically, factories use materials such as PVC or polyurethane-coated fabrics, which are known for their water-resistant properties. These materials are sourced from suppliers and then inspected for quality before being used in production.

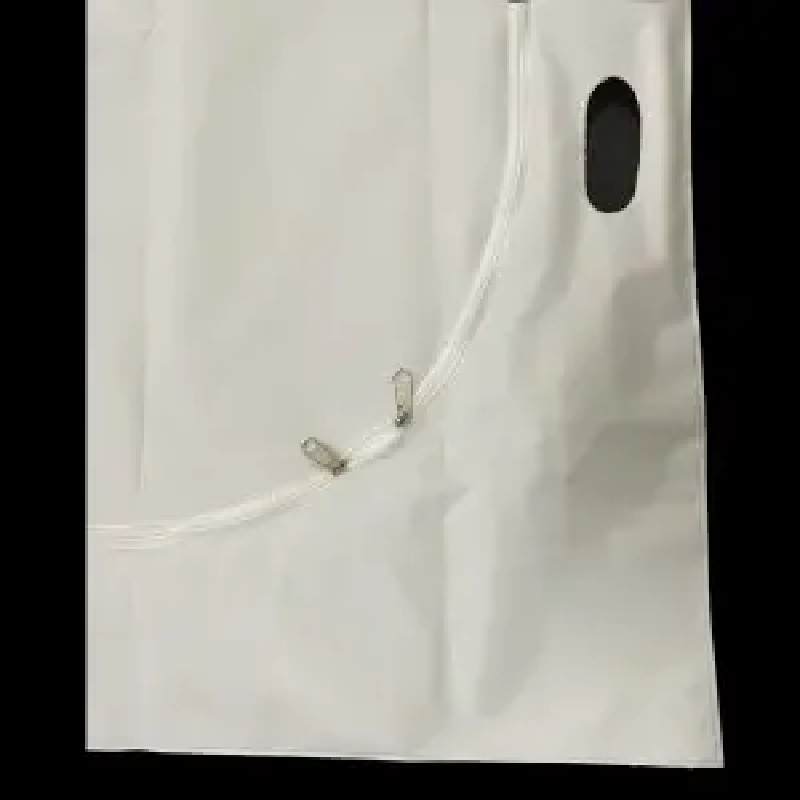

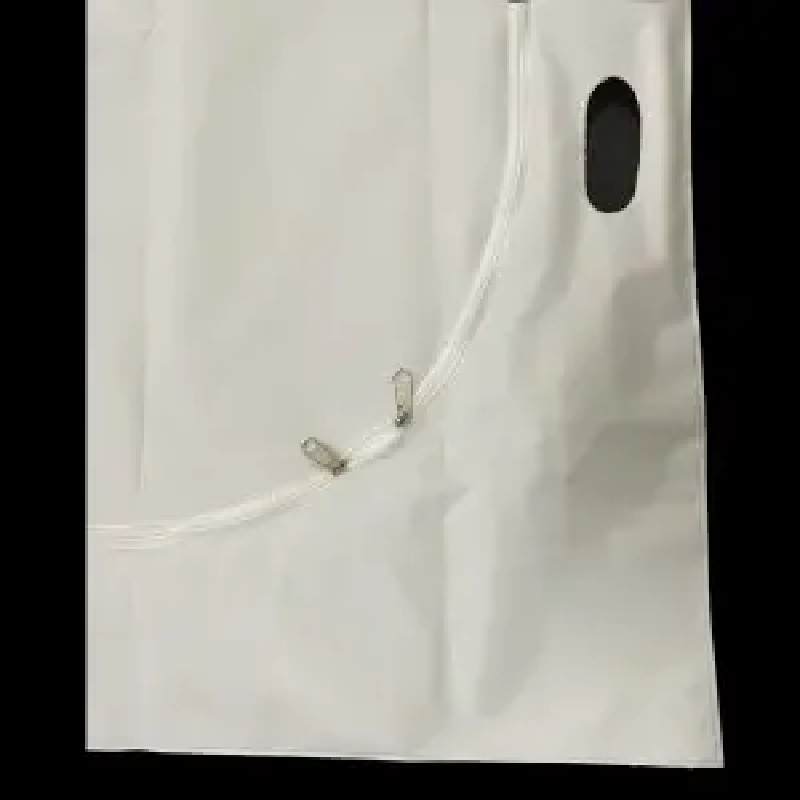

Once the materials have been selected, they are cut into patterns according to the design of the rainwear garment. This process requires precision and attention to detail to ensure that each piece is the correct size and shape. Cutting machines are often used to quickly and accurately cut the materials into the desired patterns.

After the materials have been cut, they are then sewn together to create the final product. Sewing machines are used to stitch the pieces together, forming the raincoat or poncho. This step in the manufacturing process requires skilled workers who are trained in sewing techniques to ensure that the seams are strong and durable

plastic rain wear factories. Once the garment has been sewn together, it undergoes a quality control inspection to check for any defects or imperfections. Any issues are addressed and corrected before the rainwear is packaged and prepared for shipping. In addition to the manufacturing process, plastic rainwear factories also play a role in sustainability and environmental responsibility. Many factories are implementing eco-friendly practices such as recycling scrap materials and using energy-efficient machinery to reduce their carbon footprint. Overall, plastic rainwear factories are essential in providing individuals with protection from the rain. The manufacturing process involves several steps, from selecting materials to sewing them together, all of which require skill and precision. By implementing sustainable practices, these factories are not only producing quality rainwear but also minimizing their impact on the environment. In conclusion, plastic rainwear factories are vital in creating waterproof apparel that helps people stay dry during rainy weather. Understanding the manufacturing process gives us a greater appreciation for the work that goes into producing these essential items. The next time you put on your raincoat or poncho, remember the effort that went into making it possible.

plastic rain wear factories. Once the garment has been sewn together, it undergoes a quality control inspection to check for any defects or imperfections. Any issues are addressed and corrected before the rainwear is packaged and prepared for shipping. In addition to the manufacturing process, plastic rainwear factories also play a role in sustainability and environmental responsibility. Many factories are implementing eco-friendly practices such as recycling scrap materials and using energy-efficient machinery to reduce their carbon footprint. Overall, plastic rainwear factories are essential in providing individuals with protection from the rain. The manufacturing process involves several steps, from selecting materials to sewing them together, all of which require skill and precision. By implementing sustainable practices, these factories are not only producing quality rainwear but also minimizing their impact on the environment. In conclusion, plastic rainwear factories are vital in creating waterproof apparel that helps people stay dry during rainy weather. Understanding the manufacturing process gives us a greater appreciation for the work that goes into producing these essential items. The next time you put on your raincoat or poncho, remember the effort that went into making it possible.

Latest news

-

36x90" Double Zipper Post Mortem Bag - Secure & Reliable

NewsAug.17,2025

-

Waterproof PVC/Vinyl Work Apron - Heavy-Duty Protection

NewsAug.16,2025

-

Heavy Duty Post Mortem Bag - 36x90, Double Zipper

NewsAug.15,2025

-

Durable PVC Vinyl Work Apron - Waterproof for Workshop

NewsAug.14,2025

-

Durable PVC/Vinyl Work Apron - Waterproof Workshop Protection

NewsAug.13,2025

-

Leakproof White Cadaver Bag 36x90 with Perimeter Zipper

NewsAug.12,2025