Aug . 14, 2024 01:36 Back to list

Exploring the Innovations and Challenges of Shroud Sheet Manufacturing in the Modern Industry

The Evolution and Impact of Shroud Sheet Factories

In recent years, shroud sheet factories have emerged as pivotal players within the textile manufacturing industry, responding to an increasing demand for specialized materials that cater to a variety of applications—from medical to industrial sectors. The term shroud sheet refers to materials used primarily for covering, protecting, or insulating different substances. Historically, these sheets have served essential functions, but the contemporary evolution of shroud sheet production has unveiled significant advancements in both technology and sustainable practices.

Shroud sheets are often manufactured from diverse materials, including polyethylene, polypropylene, and biodegradable options. The versatility of these materials allows shroud sheets to be tailored for different uses, offering properties such as water resistance, UV protection, and durability. For instance, in the medical field, shroud sheets are crucial for sterile environments, where they are used to cover equipment and surfaces. The cleanliness and reliability of these materials can directly impact patient care, making it vital for factories to uphold stringent quality control standards.

One of the noteworthy trends in shroud sheet factories is the integration of advanced manufacturing technologies. The incorporation of automation and computer-aided design (CAD) has streamlined production processes, enhancing efficiency and reducing waste. Automated cutting machines and sewing systems allow for precise customization of sizes and shapes, catering to the specific needs of clients. Furthermore, the adoption of eco-friendly materials and practices has gained momentum within the industry. Many factories are now focusing on producing recyclable or biodegradable shroud sheets, prompting a shift in the market towards sustainable options. This transition not only aids in environmental conservation but also addresses the growing consumer preference for sustainable products.

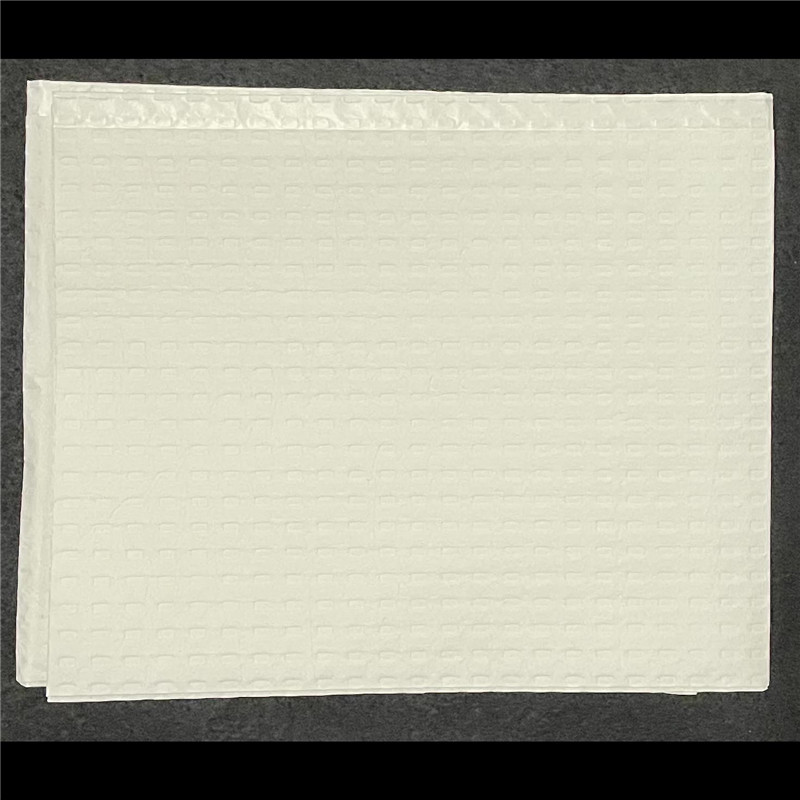

shroud sheet factories

The impact of shroud sheet factories goes beyond the materials they produce. Their operations contribute to the local economy by providing jobs and support for allied industries, such as logistics and supply chain management. As demand for shroud sheets increases globally, these factories have the potential to expand their reach and influence, driving economic growth in their respective regions. Additionally, the globalization of supply chains allows for the efficient distribution of shroud sheets, making it possible for companies in diverse sectors to access these essential materials.

Moreover, shroud sheet factories are increasingly adopting innovative practices to enhance their competitive edge. Research and development (R&D) efforts focused on improving the properties of shroud sheets—such as fire resistance, antimicrobial treatments, and even smart textiles—create opportunities for these factories to differentiate themselves in a crowded market. By continually refining their processes and expanding their product offerings, shroud sheet manufacturers can not only meet the current demands of the market but also anticipate future trends.

In conclusion, shroud sheet factories are integral to the fabric of modern manufacturing, providing essential materials that fulfill diverse applications across various industries. Through the adoption of advanced technologies and a commitment to sustainability, these factories are evolving to meet the challenges of a changing market while contributing positively to the economy and the environment. As the demand for specialized materials continues to grow, shroud sheet factories will likely play an increasingly significant role in shaping the future of textile manufacturing, proving that they are much more than just manufacturers; they are innovators and drivers of change in the industry.

-

High-Quality Body Storage Bags – Reliable Manufacturer, Factory & Exporter

NewsJul.08,2025

-

High-Quality PE Cadaver Bag for Pets Reliable Manufacturer & Supplier

NewsJul.08,2025

-

Medical Depot - Leading Medical Depot Factory, Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Work Raincoat – Reliable Manufacturer & Exporter Direct from Factory

NewsJul.07,2025

-

High-Quality Pet Dead Body Bag - Reliable Manufacturer, Factory & Exporter

NewsJul.07,2025

-

High-Quality Vinly Vest Manufacturer & Exporter Custom Vinly Vest Factory

NewsJul.06,2025