11月 . 09, 2024 06:00 Back to list

Innovative Approaches to Shroud Transport Manufacturing and Logistics Efficiency

The Evolution of Shroud Transport Factories in Modern Industry

In the ever-evolving landscape of modern manufacturing, the rise of shroud transport factories has marked a significant revolution in efficiency, innovation, and sustainability. These specialized production facilities have emerged as a critical component of supply chains, particularly in industries such as automotive, electronics, and consumer goods. They are designed to optimize the movement of products and materials, ensuring that goods are produced and delivered with minimal delays and maximum output.

Understanding Shroud Transport

At its core, shroud transport refers to the implementation of systems and processes that encase or protect products during transportation within manufacturing environments. This concept has led to the development of transport systems featuring shrouded elements—essentially protective casings that safeguard goods from damage, contamination, and external environmental factors. By wrapping products in a shroud, factories can minimize the risk of loss or deterioration, enhancing overall reliability.

Shroud transport systems leverage various advanced technologies. For instance, the integration of automated guided vehicles (AGVs) and robotic transporters has streamlined internal logistics, reducing human touchpoints and thus limiting the chances of errors or inefficiencies. These machines operate autonomously to move materials and finished products across factory floors, ensuring that processes remain uninterrupted. Additionally, advanced tracking systems, such as RFID and IoT devices, allow for real-time monitoring of goods, further enhancing traceability and inventory management.

Benefits of Shroud Transport Factories

The adoption of shroud transport factories offers numerous benefits. First and foremost, they significantly enhance operational efficiency. By minimizing manual handling and optimizing transportation routes, factories can reduce lead times and increase productivity. This boost in efficiency directly correlates with cost savings, enabling manufacturers to operate more competitively in a global market.

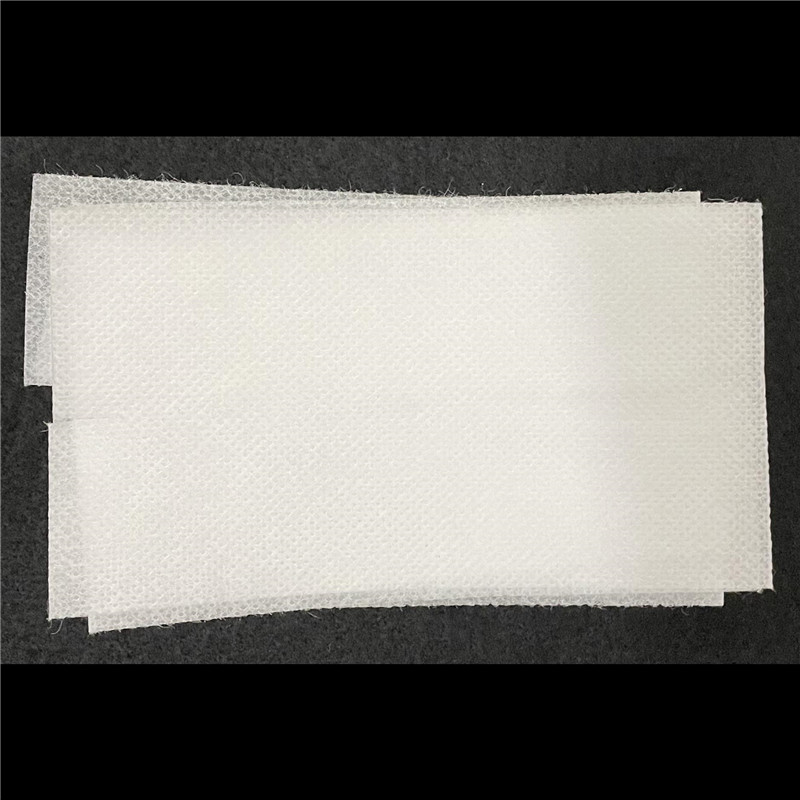

shroud transport factories

Moreover, these factories contribute to improved safety standards. With shrouded transport mechanisms, the risks associated with handling and transporting goods are substantially diminished. This not only protects the workforce but also lowers the likelihood of product damage during transit. Consequently, companies can maintain higher quality standards, ensuring customer satisfaction and loyalty.

Sustainability is another key advantage of shroud transport factories. As industries worldwide strive to reduce their environmental footprint, shrouded transport systems enable the use of recyclable and eco-friendly materials. Additionally, the improved logistics efficiency leads to reduced waste, as less energy and resources are expended during production and transportation processes.

Challenges Ahead

Despite the numerous advantages, the implementation of shroud transport factories also presents challenges. The initial investment required for advanced technologies and infrastructure can be substantial, particularly for smaller manufacturers. Furthermore, the transition from traditional systems to modern shroud-based methods necessitates a cultural shift within organizations, requiring training and adaptation on the part of the workforce.

Moreover, the reliance on advanced technology raises concerns regarding cybersecurity. As systems become more interconnected, the potential for data breaches and operational disruptions increases. Manufacturers must prioritize robust cybersecurity measures to protect their operations and sensitive information.

Conclusion

As shroud transport factories continue to gain traction in the manufacturing sector, their impact on productivity, safety, and sustainability cannot be overstated. By leveraging advanced technologies and innovative design, industries can streamline their operations and respond more effectively to market demands. While challenges remain in the adoption of these systems, the future of manufacturing is undoubtedly leaning toward a shrouded approach to transport, signaling a new era of efficiency and resilience in the face of global challenges. With the right strategies and investments, shroud transport factories are poised to lead the way to a more productive and sustainable industrial future.

-

Premium PVC Rainwear Supplier & Exporters Quality Plastic PVC Rainwear for All Weather

NewsJul.05,2025

-

High-Quality PE Cadaver Bag for Pets Reliable Pet Cadaver Bag Manufacturer & Supplier

NewsJul.05,2025

-

High Quality PEVA Rainsuit Manufacturer & Supplier Durable Waterproof Rain Gear Solutions

NewsJul.05,2025

-

High-Quality Women Rainwear Leading Women Rainwear Factory, Manufacturer, Exporter

NewsJul.04,2025

-

High Quality PVC Poncho - Heavy Duty Rain Protection from Leading Exporters & Suppliers

NewsJul.04,2025

-

Waterproof Poncho Wholesale - Reliable Waterproof Rain Poncho Manufacturers & Factories

NewsJun.24,2025