Feb . 18, 2025 11:05 Back to list

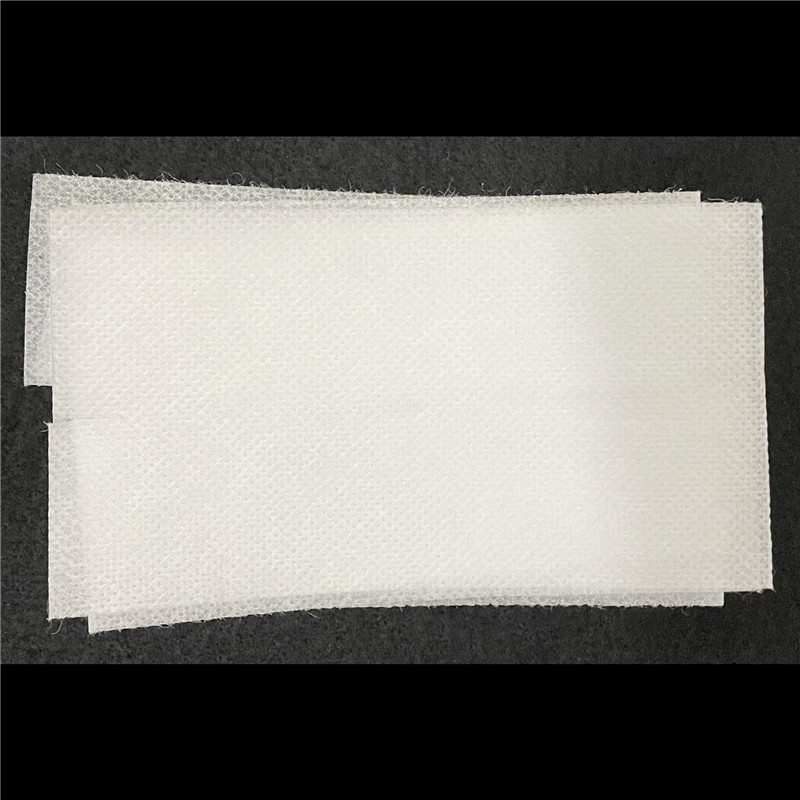

Post Mortem Bag, double zipper, 36×90 Inchs #CG23690O00

The production of animal cadaver bags is a niche, yet critical sector that plays an essential role in various industries including veterinary services, agricultural operations, and wildlife conservation. While it may not seem like the most glamorous of topics, the factories that produce these specialized bags offer a fascinating blend of technical innovation, biosecurity measures, and environmental responsibility. This article delves into the intricacies of this industry, shedding light on aspects that contribute to its growing relevance and effectiveness.

Expertise in this field also demands a deep understanding of end-user needs. For veterinary practices, the bags must be easy to seal and transport, with clear labeling for quick identification and management of different animal species. In agricultural settings, dimensions may need to accommodate larger livestock, requiring bespoke solutions. Manufacturers often work closely with end-users to refine product designs, offering customization to meet specific operational challenges effectively. Authoritativeness in this domain stems from a commitment to pioneering research and adhering to high standards. Leading factories might engage in partnerships with universities or participate in industry conferences, contributing to a global conversation about best practices in disposal technologies. Their authority is built on a foundation of ongoing innovation, knowledge dissemination, and excellent safety records. Trustworthiness is another critical component of successful manufacturing operations. Transparent sourcing of raw materials, ethical labor practices, and community engagement programs enhance the credibility of product offerings. Many factories strive to maintain open communication channels with stakeholders, from regulatory bodies to their direct customers, ensuring feedback loops enable continuous improvement in product design and application. As awareness of environmental issues grows, the industry faces the challenge of balancing functionality with ecological responsibility. Manufacturers are increasingly prioritizing product lifecycle assessments, exploring ways to reduce the carbon footprint not only of their products but throughout the entire manufacturing process. Initiatives such as recycling programs for used bags and energy-efficient production facilities underscore their commitment to sustainability. In conclusion, the narrative around animal cadaver bag factories is one of continual evolution and responsibility. Through expert craftsmanship, innovative material use, and a steadfast dedication to biosecurity and sustainability, these factories are vital components of a larger ecosystem that upholds public health standards and environmental conservation efforts. As the demand for safe, efficient, and sustainable disposal solutions grows, this sector stands at the cutting edge of providing indispensable services that benefit both human and environmental health.

Expertise in this field also demands a deep understanding of end-user needs. For veterinary practices, the bags must be easy to seal and transport, with clear labeling for quick identification and management of different animal species. In agricultural settings, dimensions may need to accommodate larger livestock, requiring bespoke solutions. Manufacturers often work closely with end-users to refine product designs, offering customization to meet specific operational challenges effectively. Authoritativeness in this domain stems from a commitment to pioneering research and adhering to high standards. Leading factories might engage in partnerships with universities or participate in industry conferences, contributing to a global conversation about best practices in disposal technologies. Their authority is built on a foundation of ongoing innovation, knowledge dissemination, and excellent safety records. Trustworthiness is another critical component of successful manufacturing operations. Transparent sourcing of raw materials, ethical labor practices, and community engagement programs enhance the credibility of product offerings. Many factories strive to maintain open communication channels with stakeholders, from regulatory bodies to their direct customers, ensuring feedback loops enable continuous improvement in product design and application. As awareness of environmental issues grows, the industry faces the challenge of balancing functionality with ecological responsibility. Manufacturers are increasingly prioritizing product lifecycle assessments, exploring ways to reduce the carbon footprint not only of their products but throughout the entire manufacturing process. Initiatives such as recycling programs for used bags and energy-efficient production facilities underscore their commitment to sustainability. In conclusion, the narrative around animal cadaver bag factories is one of continual evolution and responsibility. Through expert craftsmanship, innovative material use, and a steadfast dedication to biosecurity and sustainability, these factories are vital components of a larger ecosystem that upholds public health standards and environmental conservation efforts. As the demand for safe, efficient, and sustainable disposal solutions grows, this sector stands at the cutting edge of providing indispensable services that benefit both human and environmental health.

Latest news

-

Heavy-Duty 36x90 White Cadaver Bag with Perimeter Zipper

NewsAug.27,2025

-

White PEVA/PVC Pet Bodybag with Handle - Dignified, Secure Transport.

NewsAug.26,2025

-

100% Waterproof PVC/PEVA Kids Poncho | Hoodie Rain Wear

NewsAug.21,2025

-

PVC/PEVA Sleeves: Durable Protection for Workshop & Labour Safety

NewsAug.19,2025

-

Waterproof Kid Apron with Sleeves: PEVA/PVC for Painting Fun!

NewsAug.18,2025

-

36x90" Double Zipper Post Mortem Bag - Secure & Reliable

NewsAug.17,2025