dec . 06, 2024 20:00 Back to list

waterproof vest factories

Exploring the World of Waterproof Vest Factories

Waterproof vests have emerged as essential garments in various industries, from outdoor sports and recreation to workwear and emergency services. With the growing demand for durable and functional apparel, waterproof vest factories play a crucial role in meeting consumer needs. This article delves into the workings of these factories, their manufacturing processes, and the importance of quality in producing reliable waterproof vests.

Understanding Waterproof Vests

Waterproof vests are designed to provide both comfort and protection against the elements, particularly water. They are popular among outdoor enthusiasts, such as hikers, fishermen, and boaters, who require lightweight yet effective insulation. Additionally, waterproof vests are commonly used in professional settings where employees may encounter wet conditions, such as in construction, agriculture, and emergency response.

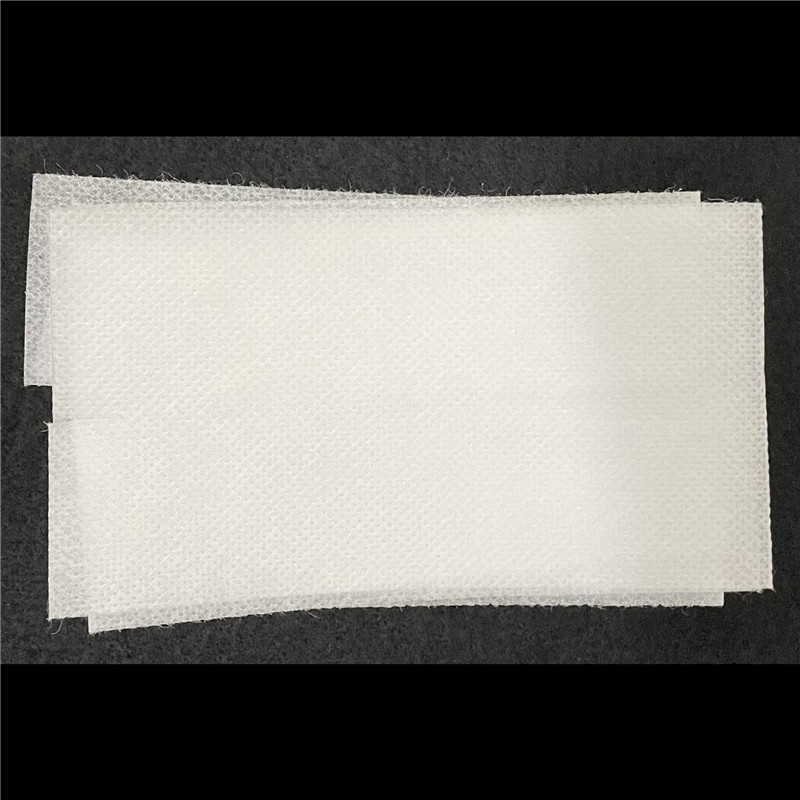

These vests are typically made from specialized materials that repel water, such as Gore-Tex, nylon, or polyester blends treated with water-resistant coatings. The construction of these garments often incorporates sealed seams and zippers to further prevent water penetration, ensuring that the wearer remains dry in soaking conditions.

The Manufacturing Process

Waterproof vest factories employ a combination of advanced technology and skilled craftsmanship to produce high-quality products. The process begins with the sourcing of materials, where manufacturers must choose the right fabric that meets both waterproof and breathability standards. This is crucial since users often face not only rain but also the need to release moisture generated from physical activity.

Once the materials are selected, the production phase commences

. It typically involves several stages1. Design and Prototyping Designers create patterns based on functional requirements, ensuring that the vest is comfortable and practical. Prototypes may be tested extensively to ensure they meet waterproof standards.

2. Cutting and Sewing The selected fabrics are cut according to the design specifications. Skilled workers sew the pieces together, often using specialized stitching techniques to enhance water resistance. Automated cutting machines can help increase efficiency and precision during this phase.

waterproof vest factories

3. Seam Sealing One of the most critical steps in manufacturing waterproof vests is seam sealing. This process involves applying adhesive tape over the stitched seams, which are points of weakness where water can leak through. Factories use heat or pressure to ensure a secure bond between the fabric and tape.

4. Quality Control After the vests are assembled, they undergo rigorous quality control tests. These tests typically include water resistance assessments, durability examinations, and overall wearability checks. Factories aim to meet specific industry standards to ensure their products' reliability.

5. Packaging and Distribution Once quality control is complete, the vests are packaged and prepared for distribution to retailers and customers worldwide.

The Importance of Quality Assurance

In the competitive apparel market, quality assurance is paramount for waterproof vest factories. Consumers are increasingly discerning when it comes to outdoor gear, prioritizing durability and effectiveness. A product that fails to perform can damage a brand's reputation and result in financial losses.

To mitigate these risks, many factories implement strict quality management systems, adhering to international standards such as ISO 9001. This ensures that every aspect of the manufacturing process, from materials sourcing to final inspection, is carefully monitored and controlled.

Sustainability in Production

As consumers become more environmentally conscious, waterproof vest factories are also exploring sustainable manufacturing practices. This includes sourcing eco-friendly materials, reducing waste through efficient cutting patterns, and implementing energy-saving technologies. By prioritizing sustainability, these factories not only meet consumer expectations but also contribute positively to the environment.

Conclusion

Waterproof vest factories are vital players in the apparel industry, providing essential garments that help protect individuals in various scenarios. Through a combination of advanced technology, skilled craftsmanship, and a focus on quality assurance, these factories create products that enhance the safety and comfort of wearers. As demand for waterproof apparel continues to grow, the industry will likely see further innovations and improvements, ensuring that consumers are equipped with the best gear to face the elements.

-

Premium PVC Rainwear Supplier & Exporters Quality Plastic PVC Rainwear for All Weather

NewsJul.05,2025

-

High-Quality PE Cadaver Bag for Pets Reliable Pet Cadaver Bag Manufacturer & Supplier

NewsJul.05,2025

-

High Quality PEVA Rainsuit Manufacturer & Supplier Durable Waterproof Rain Gear Solutions

NewsJul.05,2025

-

High-Quality Women Rainwear Leading Women Rainwear Factory, Manufacturer, Exporter

NewsJul.04,2025

-

High Quality PVC Poncho - Heavy Duty Rain Protection from Leading Exporters & Suppliers

NewsJul.04,2025

-

Waterproof Poncho Wholesale - Reliable Waterproof Rain Poncho Manufacturers & Factories

NewsJun.24,2025