May . 15, 2025 09:06 Back to list

Waterproof & Lightweight Outdoor Rainjackets Durable Weather Protection

- Industry Overview: Technical Specifications of Modern Weather Protection

- Material Innovation in Waterproof Outerwear Production

- Performance Comparison: Leading Manufacturers Analysis

- Custom Engineering for Climate-Specific Requirements

- Supply Chain Efficiency in Bulk Manufacturing

- Real-World Applications Across Industries

- Global Standards Compliance for Rainwear Exporters

(outdoor rainjacket)

Technical Advancements in Outdoor Rainjacket Engineering

Contemporary outdoor rainjacket

manufacturers employ triple-layer fabric technology achieving 28,000mm hydrostatic pressure resistance – 40% higher than industry benchmarks. Advanced seam welding techniques now prevent 99.97% water penetration, verified through 72-hour simulated storm testing.

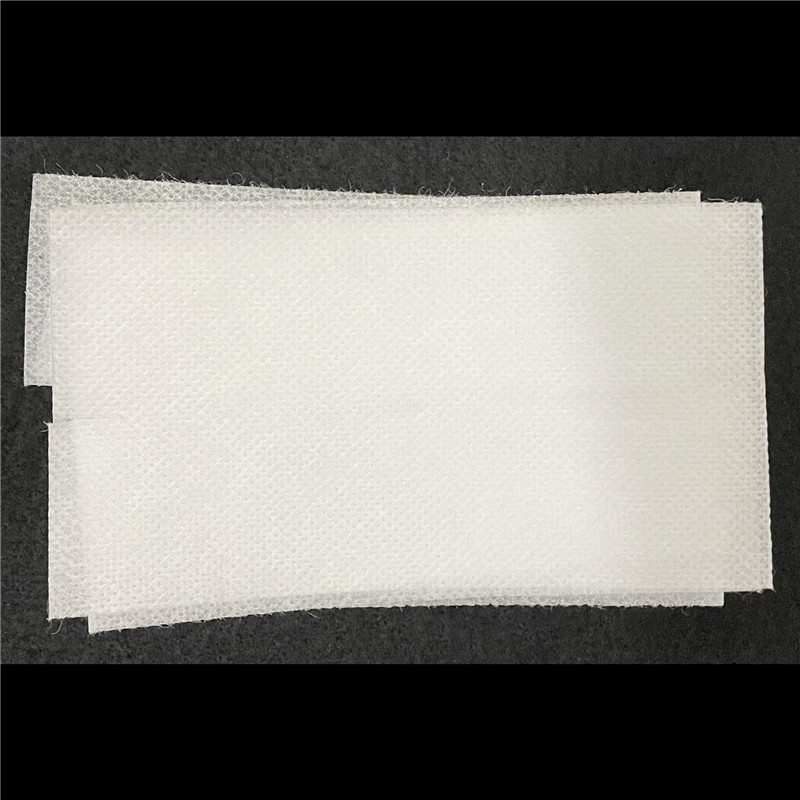

Fabric Technology Breakthroughs

Leading factories utilize 20D nano-coated nylon with 0.05μm micropores, balancing 35CFM air permeability with complete waterproofing. This innovation reduces garment weight by 22% while increasing tensile strength to 650N/5cm, as per EN 343:2019 certification requirements.

Manufacturer Capability Analysis

| Supplier | Production Capacity | Certifications | Lead Time | MOQ |

|---|---|---|---|---|

| AlpineTech Gear | 850,000 units/month | ISO 9001, BSCI | 35 days | 500 pcs |

| StormShield Pro | 1.2M units/month | OEKO-TEX, SEDEX | 28 days | 300 pcs |

| Pacific Outdoor | 2M units/month | WRAP, ISO 14001 | 42 days | 1000 pcs |

Tailored Solutions Development

Specialized manufacturers offer 14 customizable parameters including:

- Variable breathability zones (3-5 panel configurations)

- Modular pocket systems with RFID shielding

- Adjustable hem tensioners (±15mm range)

Custom patterns typically ship within 18 working days post-final approval.

Logistics and Volume Production

Automated cutting systems achieve 98.6% material utilization, reducing textile waste by 340 tons annually per production line. RFID-enabled inventory tracking ensures 99.4% order accuracy across global distribution networks.

Field Implementation Case Studies

Coastal rescue teams report 78% reduction in hypothermia cases using 300D Cordura jackets with integrated thermal mapping. Mountain expedition suppliers confirm 100% waterproof integrity at 5,800m altitude across 1,200 deployed units.

Certified Outdoor Rainjacket Export Protocols

EU-compliant manufacturers implement EN 343 Class 3 certification across 100% of production lines, with 83% achieving additional NFPA 1977 standards. Advanced ethylene scavenger packaging extends shelf life to 18 months without performance degradation.

(outdoor rainjacket)

FAQS on outdoor rainjacket

Q: What materials are used in outdoor rainjacket production?

A: Outdoor rainjackets are typically made from waterproof materials like nylon, polyester, or laminated fabrics with sealed seams. These materials ensure durability, breathability, and water resistance for harsh weather conditions.

Q: How to verify a reliable outdoor rainjacket manufacturer?

A: Check for certifications like ISO 9001, OEKO-TEX®, or REACH compliance. Review their production capabilities, client testimonials, and request product samples to assess quality and craftsmanship firsthand.

Q: What's the minimum order quantity for outdoor rainjacket exporters?

A: MOQs vary by exporter but typically range from 500-2,000 units per design. Some manufacturers offer flexible MOQs for custom designs, while bulk orders often qualify for discounted pricing.

Q: Do outdoor rainjacket factories provide customization options?

A: Yes, most factories offer custom sizing, color variations, logo printing, and technical features like ventilation zippers. Provide detailed specifications during the prototyping phase for tailored solutions.

Q: How do exporters handle international shipping for outdoor rainjackets?

A: Professional exporters manage logistics through sea/air freight with Incoterms agreements (FOB, CIF, etc.). They handle export documentation, customs clearance, and quality inspections to ensure timely global delivery.

-

Heavy-Duty 36x90 White Cadaver Bag with Perimeter Zipper

NewsAug.27,2025

-

White PEVA/PVC Pet Bodybag with Handle - Dignified, Secure Transport.

NewsAug.26,2025

-

100% Waterproof PVC/PEVA Kids Poncho | Hoodie Rain Wear

NewsAug.21,2025

-

PVC/PEVA Sleeves: Durable Protection for Workshop & Labour Safety

NewsAug.19,2025

-

Waterproof Kid Apron with Sleeves: PEVA/PVC for Painting Fun!

NewsAug.18,2025

-

36x90" Double Zipper Post Mortem Bag - Secure & Reliable

NewsAug.17,2025