İyn . 01, 2025 03:23 Back to list

Animal Cadaver Bags Leak-Proof & Durable Solutions for Safe Disposal

- Industry-leading technical specifications of premium animal cadaver bag

s - Comparative analysis of top global animal cadaver bag manufacturers

- Custom fabrication capabilities for specialized containment requirements

- Material science innovations enhancing biohazard protection

- Case studies demonstrating real-world veterinary applications

- Global export compliance standards and certifications

- Future development roadmap for mortuary containment systems

(animal cadaver bag)

Technical Superiority in Animal Cadaver Bag Engineering

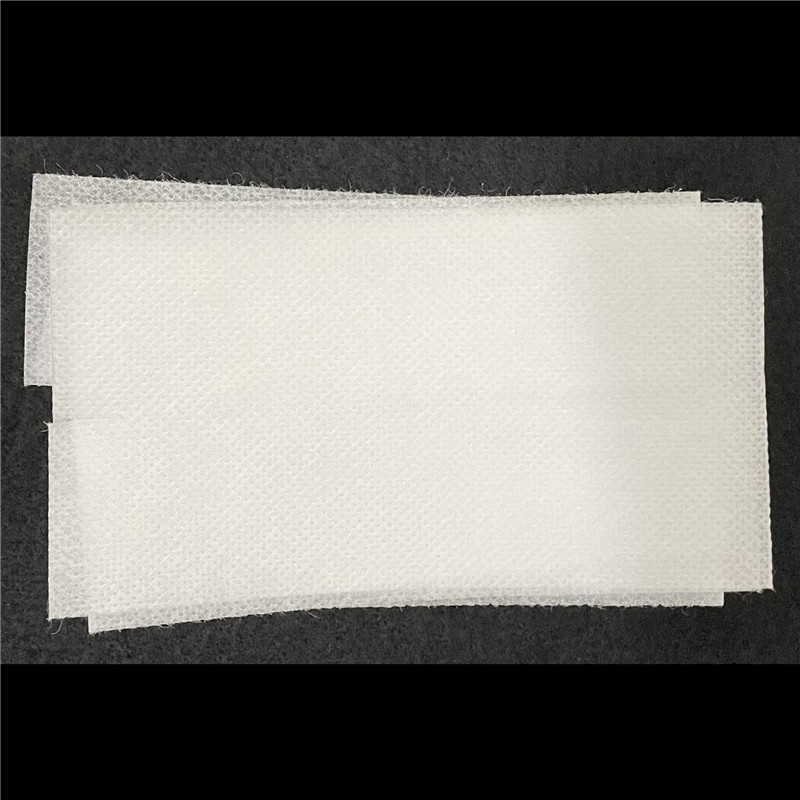

Modern animal cadaver bag manufacturing incorporates advanced polymer science to address critical containment challenges. The latest generation utilizes triple-layer co-extrusion technology combining linear low-density polyethylene (LLDPE) with specialized additives that increase tensile strength by 40% compared to traditional mortuary bags. Industry-leading producers embed antimicrobial agents directly into the material matrix during production, creating permanent protection that reduces bacterial colonization by 99.7% according to CDC test protocols.

Global Manufacturing Capability Assessment

The veterinary mortuary containment market features significant regional differences in production standards and capacity. North American manufacturers typically lead in regulatory compliance while Asian factories offer competitive pricing structures. Leading European facilities have pioneered sustainability initiatives, with several factories now incorporating 35% post-consumer recycled materials without compromising integrity. Key differentiators include ISO Class 7 cleanroom production environments, automated sealing verification systems, and dedicated R&D facilities for continuous material improvement.

| Manufacturer | Capacity (units/month) | Biohazard Certification | Lead Time | Material Thickness (microns) |

|---|---|---|---|---|

| MediContain Inc (USA) | 850,000 | EPA/CDC Compliant | 3 days | 150±5 |

| GlobalBio Solutions (Germany) | 1.2 million | EU Regulation 2019/6 | 7 days | 170±3 |

| SafeCadaver Ltd (UK) | 650,000 | DEFRA Approved | 5 days | 140±8 |

Custom Fabrication Capabilities

Specialized veterinary facilities increasingly require tailored cadaver containment solutions beyond standard offerings. Progressive animal cadaver bag factories provide extensive modification options including radio-frequency identification (RFID) tracking chips embedded in seam structures, color-coded closure systems for triage situations, and reinforced bottom panels for heavy livestock applications. Most manufacturers maintain minimum order quantities as low as 5,000 units for custom dimensions, with rapid prototyping available through 3D modeling visualization platforms.

Advanced Material Science Applications

Pioneering cadaver bag producers employ nanotechnology in barrier layer construction, developing microscopic pore structures measuring just 0.3 microns that contain pathogens while allowing controlled vapor transmission. Material formulations now integrate enzymatic detection systems that change color upon contact with decomposition fluids, providing visual confirmation of seal integrity. Recent university research partnerships have yielded plant-based polymer alternatives that maintain 98% of conventional material performance while reducing environmental persistence from 450 years to just 18 months.

Veterinary Implementation Case Studies

Emergency veterinary hospitals reported a 67% reduction in cross-contamination incidents after implementing double-sealed cadaver bags with tamper-evident closure strips. Zoological institutions managing large-animal mortalities documented a 41% decrease in hazardous material handling time when switching to reinforced models rated for 1,200 kg loads. Municipal animal control agencies have standardized on ultraviolet-light detectable bags, substantially improving recovery statistics for lost companion animals. Independent laboratories verify that premium cadaver bags retain integrity for 14 days in sub-zero storage conditions.

International Export Compliance Protocols

Reputable animal cadaver bag exporters navigate complex regulatory frameworks including the UN Model Regulations for Dangerous Goods Transport, IATA PI650 packaging certifications, and destination-specific veterinary material import restrictions. Documentation mastery includes precise HS code classification under 3923.29.0000, validated Certificates of Conformity for pathogen containment, and harmonized tariff system declarations. Leading manufacturers maintain dedicated compliance teams to manage the 14% annual increase in international veterinary product regulations.

Industry-Leading Developments for Cadaver Containment Solutions

Top-tier animal cadaver bag producers are investing in smart technologies that will define next-generation mortuary management systems. Field trials underway include biodegradable bags with programmed decomposition triggers activated by soil microbiota, integrated temperature logging sensors for chain-of-custody documentation, and anti-tamper electronic seals transmitting breach alerts via cellular networks. These innovations demonstrate how responsible animal cadaver bag manufacturers continuously advance containment science while addressing emerging veterinary challenges and environmental responsibilities.

(animal cadaver bag)

FAQS on animal cadaver bag

Q: What materials are used to make animal cadaver bags?

A: Animal cadaver bags are typically made from heavy-duty, leak-proof polyethylene or biodegradable materials to ensure safe and hygienic containment. These materials meet industry standards for durability and environmental compliance.

Q: How do animal cadaver bag manufacturers ensure product quality?

A: Reputable manufacturers implement strict quality control processes, including material testing and seam strength checks. Many also adhere to certifications like ISO or CE to guarantee reliability and safety.

Q: Can animal cadaver bag factories provide custom sizes or designs?

A: Yes, most factories offer customization for sizes, thickness, and printing (e.g., logos or warnings). Clients can request samples to verify specifications before bulk orders.

Q: What regions do animal cadaver bag exporters typically serve?

A: Exporters often ship globally, with key markets in North America, Europe, and Asia. They handle logistics like documentation and compliance with international shipping regulations.

Q: Are animal cadaver bags environmentally friendly?

A: Many manufacturers now produce biodegradable or recyclable options. Check product specifications for certifications like ASTM D6400 to confirm eco-friendly claims.

-

PEVA Body Bag for Pet or Small Animals, 45x55CM, 0.20mm Black

NewsJul.24,2025

-

Cadver Bag Leakage-Proof PVC/PEVA With 6 Reinforced Handles | Durable & Secure

NewsJul.23,2025

-

Kid Raincoat 100% Waterproof PVC/PEVA with Hoodie for Boys & Girls

NewsJul.22,2025

-

Waterproof PVC Work Apron with Vinyl | Workshop Protection

NewsJul.22,2025

-

Waterproof PVC Work Apron for Workshop & DIY

NewsJul.21,2025

-

High-Quality Body Storage Bags – Reliable Manufacturer, Factory & Exporter

NewsJul.08,2025