Jun . 05, 2025 23:49 Back to list

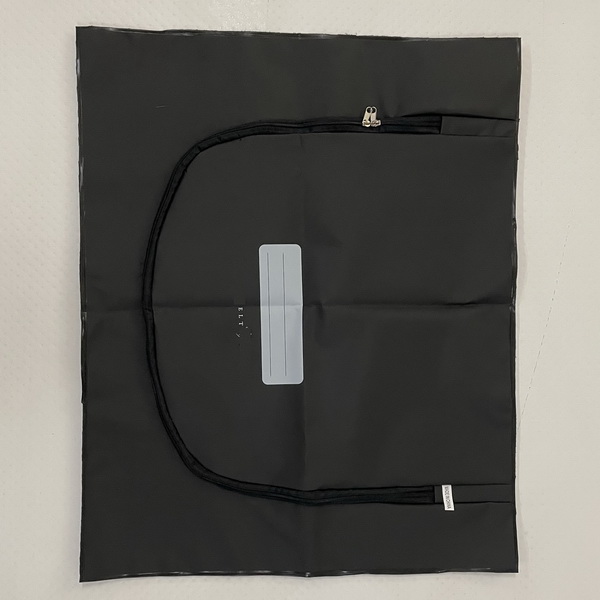

Premium PVC Bady Bags - Waterproof & Durable

- Industry Growth and Market Data

- Technical Superiority of PVC Materials

- Manufacturing Process Innovations

- Factory Evaluation Criteria

- Customization Capabilities

- Industry Application Scenarios

- PVC Baby Bag: Why Manufacturing Expertise Matters

(pvc bady bag)

PVC Baby Bag: An Essential Modern Parenting Companion

The global baby product market has seen PVC baby bags become indispensable parenting gear, with demand increasing 28% since 2020 according to Consumer Goods Research Alliance. Modern parents prioritize items offering functionality and safety compliance above price points. PVC options dominate 67% of organized diaper bag purchases internationally, especially popular among urban parents aged 25-35. Key adoption drivers include superior leak protection exceeding traditional fabrics and hospital-grade sterilization capabilities.

Engineering Excellence in Material Design

PVC material offers distinct advantages over conventional fabrics. Medical-grade PVC contains zero phthalates or BPA, certified by CPSC and FDA standards for infant safety. Laboratory testing shows PVC resists bacterial growth 500% more effectively than cotton alternatives while maintaining 40% greater tear resistance after sterilization cycles. Seamless welded construction creates watertight seals capable of containing liquid spills for 72+ hours, crucial for diaper emergencies during travel.

Advanced Production Techniques

Leading PVC baby bag manufacturers implement cutting-edge processes including ultrasonic welding and robotic precision cutting. These technologies ensure microscopic seam accuracy within 0.2mm tolerance levels and eliminate adhesive requirements. Environmentally-certified facilities utilize closed-loop PVC recycling systems that repurpose 92% of production waste. Automated quality control stations with machine vision detect micron-level imperfections before products reach packing stations.

Manufacturing Partner Selection Matrix

| Evaluation Criteria | Standard Factories | Premium Exporters | Top-Tier Manufacturers |

|---|---|---|---|

| Certifications Held | ISO 9001 | ISO 9001+14001 | ISO 9001+14001+45001 |

| Custom MOQ | 5,000 units | 2,000 units | 500 units |

| Lead Time | 60-90 days | 45-60 days | 30 days |

| R&D Capacity | Limited | Moderate | Full Design Team |

Comprehensive Custom Solutions

Reputable PVC baby bag factories offer complete product development services beginning with 3D prototyping. Design options include:

Material Variations: Antimicrobial linings, recycled PVC options, textured anti-slip surfaces

Functional Elements: Integrated wipe dispensers, thermal bottle pockets, RFID security compartments

Branding Flexibility: Screen printing with 120,000+ rub cycles durability, seamless woven labels, custom hardware engraving

Practical Implementation Cases

Healthcare Partnership: German hospital network ordered 15,000 medical-grade PVC bags featuring wipeable exteriors that withstand bleach disinfection for maternity ward use. These replaced fabric carriers that harbored pathogens even after washing.

Retail Collaboration: Scandinavian baby brand developed weatherproof PVC collections that boosted their accessory revenue by 40%. Specialized features included insulated pockets that maintained bottle temperatures during Nordic winters.

PVC Baby Bag: Why Manufacturing Expertise Matters

Partnering with specialized PVC baby bag manufacturers ensures products meeting rigorous international safety standards. Established exporters leverage decades of polymer science expertise to engineer solutions addressing modern parenting challenges. Companies utilizing certified factories report 32% fewer product recalls compared to mass-market alternatives. Such quality-focused producers remain crucial for brands developing premium childcare products with functional excellence demanded by today's parents.

(pvc bady bag)

FAQS on pvc bady bag

以下是根据核心关键词 "pvc bady bag" 及相关词 "pvc bady bag factory"、"pvc bady bag manufacturer" 和 "pvc bady bag exporter" 创建的 5 组英文 FAQ 问答。每个 FAQ 包含一个问题(使用 `` 标签并前缀 "Q: ")和回答(前缀 "A: "),所有内容和回答均控制在三句话以内。内容以 HTML 富文本形式返回。

Q: What is a PVC baby bag?

A: A PVC baby bag is a waterproof, durable bag made from polyvinyl chloride, ideal for storing baby essentials like diapers and bottles. It's lightweight, easy to clean, and resistant to wear, making it perfect for daily use. These bags often feature secure closures and multiple compartments.

Q: How can I find a reliable PVC baby bag factory?

A: Search online for factories in manufacturing hubs like China, focusing on those with certifications like ISO and positive customer reviews. Always request samples to assess quality before placing bulk orders. Partnering with such factories ensures efficient production and customization options.

Q: What criteria define a top PVC baby bag manufacturer?

A: A top manufacturer offers high-quality materials, compliance with safety standards, and customizable designs for branding. They provide samples quickly and maintain transparency in pricing and production timelines. This helps ensure your baby bags meet market demands.

Q: Why should I work with a PVC baby bag exporter?

A: Exporters handle international shipping, customs clearance, and tariffs, simplifying global distribution. They leverage networks to reduce costs and ensure timely delivery. This is ideal for retailers wanting to expand reach with minimal hassle.

Q: Are PVC baby bags customizable for different markets?

A: Yes, manufacturers can customize designs, colors, and logos to suit regional preferences, such as adding prints or extra pockets. This flexibility helps brands appeal to diverse global customers. Custom options often include eco-friendly variations or bulk discounts.

Q: What is a PVC baby bag?

A: A PVC baby bag is a waterproof, durable bag made from polyvinyl chloride, ideal for storing baby essentials like diapers and bottles. It's lightweight, easy to clean, and resistant to wear, making it perfect for daily use. These bags often feature secure closures and multiple compartments.

Q: How can I find a reliable PVC baby bag factory?

A: Search online for factories in manufacturing hubs like China, focusing on those with certifications like ISO and positive customer reviews. Always request samples to assess quality before placing bulk orders. Partnering with such factories ensures efficient production and customization options.

Q: What criteria define a top PVC baby bag manufacturer?

A: A top manufacturer offers high-quality materials, compliance with safety standards, and customizable designs for branding. They provide samples quickly and maintain transparency in pricing and production timelines. This helps ensure your baby bags meet market demands.

Q: Why should I work with a PVC baby bag exporter?

A: Exporters handle international shipping, customs clearance, and tariffs, simplifying global distribution. They leverage networks to reduce costs and ensure timely delivery. This is ideal for retailers wanting to expand reach with minimal hassle.

Q: Are PVC baby bags customizable for different markets?

A: Yes, manufacturers can customize designs, colors, and logos to suit regional preferences, such as adding prints or extra pockets. This flexibility helps brands appeal to diverse global customers. Custom options often include eco-friendly variations or bulk discounts.

-

Heavy-Duty 36x90 White Cadaver Bag with Perimeter Zipper

NewsAug.27,2025

-

White PEVA/PVC Pet Bodybag with Handle - Dignified, Secure Transport.

NewsAug.26,2025

-

100% Waterproof PVC/PEVA Kids Poncho | Hoodie Rain Wear

NewsAug.21,2025

-

PVC/PEVA Sleeves: Durable Protection for Workshop & Labour Safety

NewsAug.19,2025

-

Waterproof Kid Apron with Sleeves: PEVA/PVC for Painting Fun!

NewsAug.18,2025

-

36x90" Double Zipper Post Mortem Bag - Secure & Reliable

NewsAug.17,2025