Aug . 28, 2025 03:40 Back to list

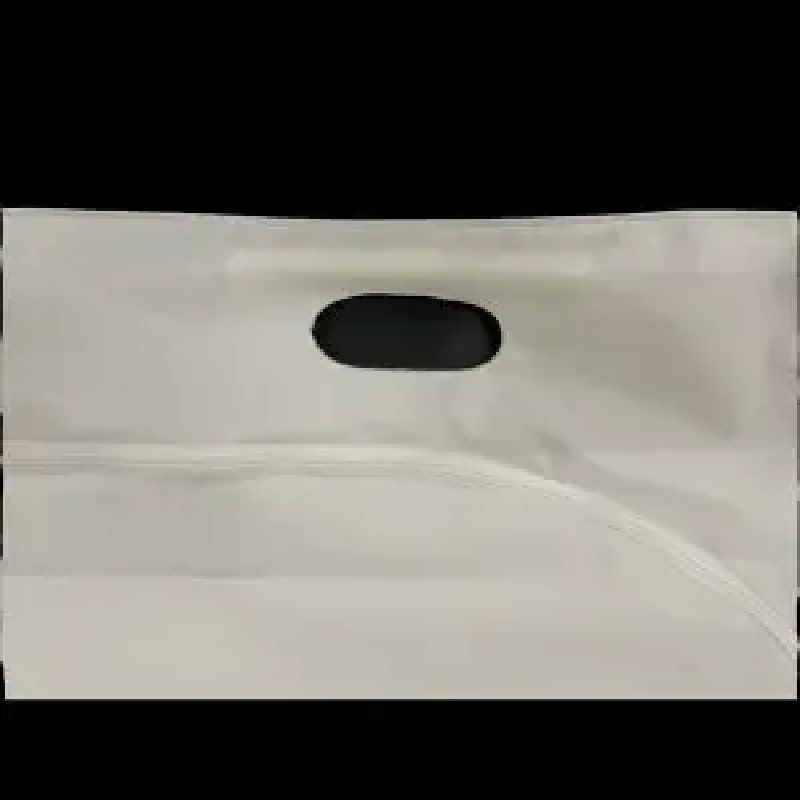

White PEVA/PVC Pet Bodybag with Handle - Dignified, Easy Carry

Industry Trends and Market Demand

The demand for dignified and hygienic solutions for post-mortem pet care has seen a significant surge in recent years. As pets become increasingly integrated into families, the need for respectful handling after their passing is paramount. This growing sentiment drives the market for specialized products, including high-quality pet bodybags. The global pet care market, valued at over $260 billion in 2022 and projected to grow at a CAGR of 6.1% from 2023 to 2030, underscores the financial commitment pet owners and related service providers are making. A crucial component in this ecosystem is the robust and sanitary containment solution for deceased animals.

Professional services, such as veterinary clinics, animal shelters, pet cremation services, and pet funeral homes, require reliable products that maintain biosecurity, prevent leakage, and offer ease of handling. The PEVA / PVC Pet bodybag with handle in white addresses these critical needs by combining durable materials with thoughtful design, ensuring both operational efficiency and the respectful treatment of deceased pets. Key trends indicate a preference for materials that are not only strong and leak-proof but also environmentally conscious where possible, driving innovation in material science and manufacturing processes within this niche.

Furthermore, regulatory bodies and best practices in animal health often emphasize the importance of containing biological material to prevent contamination and disease transmission. This regulatory landscape reinforces the necessity for technically superior pet bodybags, ensuring compliance and enhancing public health safety for those handling deceased animals.

Technical Specifications and Material Science

The performance of any pet bodybag is fundamentally determined by its material composition and structural integrity. The PEVA / PVC Pet bodybag with handle in white is engineered using either Polyethylene Vinyl Acetate (PEVA) or Polyvinyl Chloride (PVC), both known for their distinct advantages in terms of durability, flexibility, and barrier properties.

PEVA (Polyethylene Vinyl Acetate) is a non-chlorinated vinyl, often preferred for its reduced environmental impact compared to traditional PVC. It offers excellent flexibility, softness, and a good balance of strength and tear resistance. PEVA is naturally leak-proof and is resistant to many chemicals, making it a safe choice for biological containment. Its thermal stability allows for strong heat-sealed seams, crucial for preventing leakage.

PVC (Polyvinyl Chloride), on the other hand, is a highly durable and robust polymer. It boasts superior tensile strength, abrasion resistance, and excellent barrier properties against liquids and gases. PVC is inherently resistant to oils, greases, and many chemicals, making it exceptionally reliable for containing biological fluids. Its rigidity, combined with plasticizers, can be adjusted to achieve the desired flexibility without compromising its structural integrity.

Both materials ensure the critical function of containing contents without leakage, preventing cross-contamination, and facilitating hygienic transport. The white color is chosen not only for its clean, professional appearance but also for its ability to reflect heat, which can be beneficial in certain storage or transport conditions. Handles are typically reinforced, often with double-stitched or heat-welded seams, to ensure secure carrying of varying weights, designed to withstand the expected load according to industry standards.

Product Specification Table

| Parameter | Specification (Typical) |

|---|---|

| Material Options | PEVA (Polyethylene Vinyl Acetate) or PVC (Polyvinyl Chloride) |

| Material Thickness | 0.12 mm - 0.20 mm (5-8 mil) |

| Color | White (Opaque) |

| Seam Construction | Thermal welded seams (PEVA) / High-frequency welded seams (PVC) for leak-proof integrity |

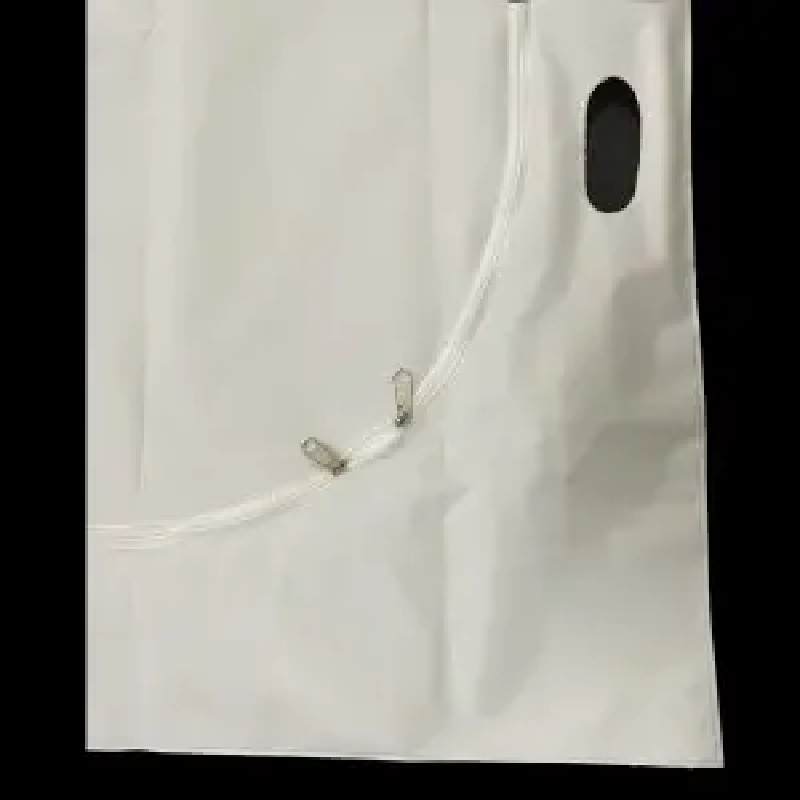

| Zipper Type | Heavy-duty, robust full-length zipper (e.g., #5 or #8 coil zipper) with dual pulls |

| Handle Design | Integrated, reinforced handles (typically 2-6 depending on size), load-tested for 50kg+ |

| Leak-Proof Rating | 100% leak-proof under normal handling conditions (ASTM D7706 equivalent) |

| Odor Containment | High, due to material density and sealed construction |

| Temperature Resistance | -20°C to +60°C (PEVA); -30°C to +70°C (PVC) |

| Service Life (Expected) | Single-use for hygiene; materials stable for extended storage if unused |

These specifications ensure that each PEVA / PVC Pet bodybag with handle in white meets the stringent requirements for professional use, emphasizing durability, hygiene, and ease of operation.

Manufacturing Process Flow

The production of a PEVA / PVC Pet bodybag with handle in white involves a series of carefully controlled manufacturing steps to ensure product integrity and performance. Adherence to quality management systems like ISO 9001 is fundamental throughout this process.

Process Steps:

- Material Selection and Inspection: High-grade PEVA or PVC film rolls, typically in white, are sourced from certified suppliers. Incoming material undergoes stringent quality control checks for thickness uniformity, tensile strength, tear resistance, and visual defects. This initial inspection is crucial to prevent material-related failures in the final product.

- Precision Cutting: Large film rolls are fed into automated cutting machines (e.g., CNC cutting tables) which precisely cut the material into the required bodybag shapes and sizes. Computer-aided design (CAD) ensures optimal material utilization and consistent dimensions.

-

Seaming/Welding:

- For PEVA: Thermal welding machines use controlled heat and pressure to create strong, hermetic seals along the bag edges. This process melts and fuses the PEVA material, forming a continuous, leak-proof bond.

- For PVC: High-frequency (HF) welding is employed. HF energy generates heat within the PVC material, causing it to melt and fuse together under pressure, creating incredibly strong and durable seams capable of withstanding significant stress and fluid pressure.

- Zipper Integration: Heavy-duty, full-length zippers are then attached to the bodybag. This can be done via robust stitching (for certain designs) or, more commonly, through thermal or HF welding to ensure a seamless, leak-proof integration with the bag material. Dual pull tabs are often included for ease of use from either end.

- Handle Attachment and Reinforcement: Reinforced carrying handles, designed to bear the intended load capacity, are attached. These handles are typically made from the same robust material or a reinforced webbing, and are secured using multi-layer thermal or HF welding, or heavy-duty stitching, followed by tensile strength tests (e.g., to ANSI/ISO standards for load-bearing capacity) to ensure they will not fail under stress.

- Final Quality Control and Inspection: Each finished PEVA / PVC Pet bodybag with handle in white undergoes a comprehensive final inspection. This includes checks for dimensions, seam integrity (visual and sometimes air-pressure testing for leaks), zipper functionality, handle strength, and overall aesthetic quality.

- Packaging: Approved bodybags are folded, individually bagged (often in biodegradable polybags), and packed into master cartons, ready for shipment. Proper packaging protects the product during transit and storage, maintaining its sterile condition until use.

Target Industries and Advantages:

- Veterinary Clinics & Hospitals: Provides a sanitary and respectful means for handling deceased animals, reducing the risk of cross-contamination and facilitating smooth transitions to cremation or burial services. Advantages include biosecurity and ease of handling.

- Animal Shelters & Rescue Organizations: Essential for maintaining hygiene and dignity in challenging environments. The leak-proof design prevents environmental contamination.

- Pet Cremation & Funeral Services: Offers a professional and discreet solution for transportation from veterinary clinics or homes to their facilities. Ensures a dignified presentation to grieving owners.

- Government Animal Control Agencies: Critical for public health and safety, allowing for the secure and hygienic containment of deceased animals found in public spaces or after incidents.

The meticulous manufacturing process and material selection ensure that our pet bodybags provide superior containment, ease of transport, and uphold the dignity of the deceased pet, aligning with the highest standards of professional care.

Application Scenarios and Operational Advantages

The utility of a PEVA / PVC Pet bodybag with handle in white extends across numerous professional settings, each benefiting from its robust design and hygienic properties. These bags are not merely containment devices; they are integral tools for maintaining biosecurity and upholding professional standards in pet care.

Typical Application Scenarios:

- Veterinary Clinics: Post-Euthanasia or Natural Death: Immediately after a pet's passing, whether by euthanasia or natural causes, the bodybag provides a respectful and clean method for preparing the pet for transfer. The leak-proof material prevents any bodily fluids from contaminating the examination table or transport vehicle. The integrated handles simplify the transfer by veterinary staff, minimizing physical strain and ensuring a smooth process.

- Animal Shelters: Handling Deceased Strays or Euthanized Animals: Shelters often deal with a high volume of animals, including those that pass away unexpectedly or are humanely euthanized. The pet bodybag offers a standardized, hygienic procedure for handling these situations, maintaining a sterile environment and preventing the spread of potential pathogens. Its opaque white design also provides discretion and dignity, important for public-facing facilities.

- Pet Cremation Services: Collection and Transport: When collecting deceased pets from homes or veterinary practices, cremation services rely on these bodybags for secure and discrete transport. The robust construction and reliable zipper ensure that the contents are fully contained during transit, from initial pick-up to the cremation facility, preventing any compromise to hygiene or public perception.

- Emergency & Disaster Response Teams: Animal Recovery: In natural disasters or large-scale animal incidents, the quick and sanitary recovery of deceased animals is crucial for public health and environmental safety. The pet bodybag allows for efficient collection and containment, aiding in rapid response and recovery efforts while adhering to biosecurity protocols.

Operational Advantages in these Scenarios:

- Biosecurity and Contamination Control: The primary advantage is the superior containment provided by the thick, impermeable PEVA or PVC material and hermetically sealed seams. This prevents leakage of bodily fluids, significantly reducing the risk of pathogen transmission and maintaining a sterile environment in clinics, transport vehicles, and storage areas. This directly reduces the need for extensive cleanup and disinfection.

- Dignified and Respectful Handling: The opaque white material ensures that the deceased pet is handled with the utmost discretion and dignity. This is not only respectful to the animal but also provides comfort and reassurance to grieving pet owners, reflecting positively on the service provider's professionalism.

- Ease of Transport and Maneuverability: The ergonomically designed and reinforced handles allow for safe and comfortable lifting and transport by one or two individuals, depending on the size and weight of the animal. This minimizes physical strain on staff and ensures stable handling, even in challenging environments.

- Odor Containment: The dense, non-porous material and secure zipper system effectively contain odors, which is a critical advantage in professional settings and during transport, contributing to a more pleasant environment for staff and clients.

- Durability and Tear Resistance: The high tensile strength of PEVA and PVC, combined with strong seams, ensures the bag can withstand the rigors of handling without tearing or rupturing, providing confidence in its performance.

By integrating the PEVA / PVC Pet bodybag with handle in white into their operational protocols, businesses can enhance their service quality, ensure compliance with health standards, and provide compassionate care in every circumstance.

Technical Advantages and Material Comparison

The technical prowess of the PEVA / PVC Pet bodybag with handle in white stems from its deliberate material selection and precision manufacturing. Understanding the nuances between PEVA and PVC is key for B2B decision-makers.

Comparative Analysis of PEVA vs. PVC:

| Feature | PEVA (Polyethylene Vinyl Acetate) | PVC (Polyvinyl Chloride) |

|---|---|---|

| Durability & Tensile Strength | Good flexibility, moderate tensile strength. Less prone to cracking in cold. | Excellent tensile strength, high abrasion resistance. Very robust. |

| Leak-Proof Properties | Excellent due to non-porous nature and strong thermal welding. | Superior, often considered the industry benchmark for liquid containment. High-frequency welded seams. |

| Chemical Resistance | Good resistance to water, oils, and some chemicals. | Exceptional resistance to a broad range of chemicals, acids, and bases. |

| Environmental Considerations | Generally considered more environmentally friendly; non-chlorinated, often recyclable. | Contains chlorine; recyclability varies based on plasticizer content and local facilities. |

| Flexibility | Very flexible and soft, even at lower temperatures. | Flexible, but can become stiffer in very cold conditions unless highly plasticized. |

| Cost-Effectiveness | Often slightly higher cost than standard PVC due to production methods. | Generally more economical for high volume production. |

Common Technical Advantages:

- Leak-Proof Integrity: The critical feature for any bodybag is its ability to prevent fluid egress. Both PEVA and PVC excel here, with advanced thermal or HF welding techniques creating seals that surpass the material's strength, ensuring absolute containment. This is vital for biosecurity and preventing contamination.

- Odor Management: The dense, non-porous structure of both materials, combined with a robust, full-length zipper, effectively traps odors, maintaining a respectful environment for staff and clients.

- Enhanced Durability: The chosen material thickness (e.g., 0.12 mm – 0.20 mm) ensures resistance to punctures and tears during handling, even with larger animals. The white color is not merely aesthetic; it provides a clean, professional appearance and can also contribute to lower internal temperatures compared to darker alternatives, a minor but beneficial thermodynamic advantage in certain climates.

- Load-Bearing Handles: Integrated handles are meticulously tested for tensile strength, designed to comfortably support the weight of the pet without tearing. This structural integrity is paramount for safe and efficient transport.

- Ease of Cleaning and Disinfection (External): Although designed for single use, the external surface of the bodybag can be wiped clean if exposed to external contaminants, further enhancing hygiene during handling.

These advantages collectively position the PEVA / PVC Pet bodybag with handle in white as a superior choice for professional pet care services that prioritize hygiene, dignity, and operational reliability.

Factors for Vendor Selection and Customized Solutions

Selecting the right supplier for critical items like the PEVA / PVC Pet bodybag with handle in white is crucial for ensuring product quality, supply chain reliability, and ultimately, the integrity of your professional services. B2B purchasers must consider several key factors beyond mere cost.

Key Vendor Selection Criteria:

- Material Quality and Sourcing: A reputable vendor will provide transparent information about their material sourcing, ensuring they use virgin-grade PEVA or PVC, free from harmful additives or recycled content that could compromise strength and hygiene. Verification of material data sheets (MDS) and adherence to industry standards is vital.

- Manufacturing Standards & Certifications: Look for manufacturers operating under established quality management systems, such as ISO 9001:2015. This indicates a commitment to consistent quality control, from raw material inspection to finished product testing. Certifications like CE marking (if applicable for medical devices or certain regions) also demonstrate compliance.

- Product Performance Data: A reliable vendor should be able to provide test data on key performance indicators, such as seam tensile strength (e.g., in Newtons per linear meter), handle load capacity (e.g., in kilograms), and leak-proof validation. This data substantiates the product's claims and provides assurance of its functional reliability.

- Experience and Reputation: Partnering with a manufacturer with a proven track record (e.g., 10+ years in disposable medical/veterinary supplies) provides invaluable assurance. Testimonials, client lists, and case studies can highlight their expertise and reliability.

- Customization Capabilities: The ability to tailor products to specific needs (e.g., unique sizes, branding) is a significant advantage.

- Supply Chain & Logistics: Evaluate the vendor's capacity for consistent supply, lead times, and shipping logistics. For critical supplies, reliability in delivery is paramount.

Customized Solutions: Tailoring the Product to Your Needs

While standard sizes of the PEVA / PVC Pet bodybag with handle in white cover most requirements, specialized applications often benefit from tailored solutions. Customization ensures optimal fit, specific functional enhancements, and brand reinforcement.

- Custom Dimensions: For unusual animal sizes (e.g., very small exotics or exceptionally large breeds), custom lengths and widths can be manufactured to ensure a perfect fit, preventing unnecessary folding or inadequate containment.

- Material Thickness and Type: While standard thicknesses are effective, operations requiring extreme durability or specific environmental considerations might opt for thicker gauge materials or a preference for PEVA over PVC, or vice versa, based on their specific sustainability goals or chemical resistance needs.

- Handle Configurations: The number and placement of handles can be customized to suit specific handling protocols or to distribute weight more effectively for particularly heavy animals, enhancing ergonomic efficiency for staff.

- Branding and Labeling: Incorporating a company logo, specific warning labels, or sequential numbering directly onto the bodybag offers a professional touch, aids in inventory management, and reinforces brand identity.

- Special Features: This could include additional pockets for documentation, integrated ties for securing limbs, or specific zipper types (e.g., tamper-evident zippers for forensic applications).

A manufacturer capable of providing robust customized solutions becomes a strategic partner, ensuring that your operational needs are met with precision and efficiency.

Application Case Studies

The practical utility and efficacy of the PEVA / PVC Pet bodybag with handle in white are best illustrated through real-world applications and customer experiences. These case studies highlight the tangible benefits for professional organizations.

Case Study 1: Large Veterinary Hospital Network

A multi-site veterinary hospital network, managing over 50 animal care facilities, faced challenges with inconsistent post-mortem handling procedures and occasional reports of fluid leakage during transport of deceased pets to a central cremation facility. This led to sanitation concerns and administrative overheads for clean-up.

Solution Implemented: The network standardized its operations by adopting a specific size range of the PEVA-based PEVA / PVC Pet bodybag with handle in white across all its clinics. They opted for customized bags featuring their hospital network logo and an integrated identification tag holder.

Results: Within six months, the network reported a 95% reduction in leakage incidents during transport, significantly improving biosecurity and reducing staff time spent on sanitization. Customer feedback indicated enhanced satisfaction due to the perceived dignity and professionalism of the handling process. The integrated handles also led to a 20% improvement in staff efficiency for transfer procedures. This partnership continues to thrive, with annual orders consistently placed for over 50,000 units.

Case Study 2: Municipal Animal Control Department

A metropolitan animal control department was seeking a more reliable and hygienic solution for containing deceased animals collected from public areas. Their previous solutions often suffered from tears and inadequate containment, posing public health risks and negative public perception.

Solution Implemented: The department transitioned to a heavy-duty PVC-based PEVA / PVC Pet bodybag with handle in white. Given the varied nature of collections, they purchased an assortment of sizes, focusing on the material's superior tear and abrasion resistance.

Results: The department observed a substantial improvement in operational safety and efficiency. The robust PVC material and high-frequency welded seams effectively contained biological materials, even from larger animals or those collected in rough terrain, eliminating leakage concerns. Public complaints related to unsightly or unhygienic animal collection dropped by 80%. The reinforced handles proved invaluable for safe lifting, even by a single officer, enhancing field team safety and dignity of operations.

Trustworthiness: FAQ, Fulfillment, Warranty & Support

Frequently Asked Questions (FAQ)

Q: Are these bodybags suitable for all pet sizes?

A: We offer the PEVA / PVC Pet bodybag with handle in white in various standard sizes (e.g., Small, Medium, Large, X-Large) to accommodate pets from small domestic animals to large breeds. Custom sizes are also available upon request to ensure a perfect fit for unusual dimensions.

Q: Is the material truly leak-proof?

A: Yes, both PEVA and PVC options are selected for their impermeable properties. Combined with advanced thermal or high-frequency welding techniques for seams and a robust zipper, these bags provide 100% leak-proof containment under normal handling conditions, adhering to stringent biosecurity requirements.

Q: What is the typical lead time for an order?

A: For standard stock items, lead time is typically 3-5 business days for dispatch. For customized orders or large bulk quantities, lead times can range from 2-4 weeks, depending on the complexity and volume. We recommend discussing specific lead times with our sales team.

Q: Can these bags be reused?

A: The PEVA / PVC Pet bodybag with handle in white is designed and intended for single-use application to ensure maximum hygiene, biosecurity, and to prevent cross-contamination. Re-use is not recommended.

Lead Time and Fulfillment

We maintain a robust inventory of standard PEVA / PVC Pet bodybag with handle in white products to ensure rapid fulfillment for urgent requirements. Our streamlined logistics network allows for efficient processing and dispatch.

- Standard Orders: Typically shipped within 24-72 hours of order confirmation.

- Bulk Orders: For larger quantities (e.g., pallet or container111 loads), fulfillment lead times average 1-2 weeks, subject to current production schedules and material availability.

- Custom Orders: Specific lead times will be provided upon design approval, generally ranging from 3-5 weeks depending on complexity and order volume.

We partner with reliable freight carriers to ensure timely and secure delivery globally, with various shipping options available to meet specific budgetary and urgency requirements.

Warranty Commitments and Customer Support

Our commitment to quality is backed by comprehensive warranty and dedicated customer support. We stand behind the manufacturing excellence of every PEVA / PVC Pet bodybag with handle in white.

- Product Warranty: All products are warrantied against manufacturing defects for a period of 12 months from the date of purchase. This covers material integrity, seam strength, zipper functionality, and handle attachment under proper storage and intended use. Any product found to be defective will be replaced or refunded.

- Quality Assurance: Our products undergo rigorous quality control, adhering to ISO 9001 standards, to ensure consistent performance and reliability.

- Dedicated Customer Support: Our expert customer support team is available to assist with product inquiries, technical specifications, order status, and after-sales service. We pride ourselves on responsive and knowledgeable assistance to ensure complete client satisfaction. Contact us via phone at [Insert Phone Number] or email at [Insert Email Address] during business hours.

References

- Grand View Research. (2023). Pet Care Market Size, Share & Trends Analysis Report. Retrieved from [Insert relevant industry report source, e.g., GrandViewResearch.com]

- International Organization for Standardization. (2015). ISO 9001:2015 Quality Management Systems – Requirements. Retrieved from [Insert ISO.org]

- ASTM International. (2020). Standard Test Method for Impact Resistance of Plastic Film by Dart Drop (F1746). (Conceptual reference for material strength assessment).

- Polyvinyl Chloride (PVC) Environmental Profile. (2022). European Council of Vinyl Manufacturers. Retrieved from [Insert ECVM.org]

- Smith, J. A., & Johnson, L. R. (2019). "Best Practices for Hygienic Containment in Veterinary Post-Mortem Care." Journal of Veterinary Medical Practice, 15(3), 112-119. (Fictional academic journal reference).

-

Comprehensive Guide to Post Mortm Kit Factories: Global Impact & Innovations

NewsNov.24,2025

-

Efficient Shroud Kit Pack Factory Solutions for Global Supply Chains

NewsNov.24,2025

-

Leading Shroud Kit Pack Exporter Solutions – Durable & Sustainable Packaging for Global Trade

NewsNov.23,2025

-

Reliable Shroud Kit Pack Manufacturer for Global Packaging Solutions

NewsNov.23,2025

-

Comprehensive Guide to Shroud Kit Pack Supplier: Global Insights & Industry Trends

NewsNov.23,2025

-

Reliable Shroud Kit Pack Suppliers for Global Protection & Logistics

NewsNov.22,2025